Guidelines for Canadian drinking water quality: Operational parameters

Guideline technical document

for public consultation

Consultation period ends

May 31, 2024

Purpose of consultation

This guideline technical document outlines the evaluation of the available information on calcium, magnesium, hardness, chloride, sulphate, total dissolved solids (TDS) and hydrogen sulphide with the intent of updating the guideline value for these operational parameters in drinking water. The purpose of this consultation is to solicit comments on the proposed guidelines for operational parameters, on the approach used for their development, and on the potential impacts of implementing them.

There are seven existing guideline technical documents, one for each of calcium, magnesium, hardness, chloride, sulphate, TDS and hydrogen sulphide. This document consolidates and updates information for these seven parameters into one document and proposes guidelines for these operational parameters (such as substances in the water that may affect water treatment and consumer acceptance of drinking water).

The existing guideline technical document on:

- calcium, developed in 1987 and reaffirmed in 2005, determined that a maximum acceptable concentration (MAC) was not required as there was no evidence of health effects attributable to calcium in drinking water. There were insufficient data to establish an aesthetic objective (AO). This document does not propose an AO or a MAC for calcium. Instead, calcium is addressed through information on controlling hardness.

- magnesium, developed in 1978, determined that a MAC was not required as there was no evidence of health effects attributable to magnesium in drinking water. This document does not propose an AO or a MAC for magnesium. Instead, magnesium is addressed through information on controlling hardness.

- hardness, developed in 1979, determined that a MAC was not required as the major contributors to hardness (calcium and magnesium) were not of public health concern. This document does not propose an AO or a MAC for hardness. Instead, it provides treatment and operational guidance to control hardness in drinking water treatment systems.

- chloride, developed in 1979 and reaffirmed in 2005, established an AO of ≤ 250 mg/L based on taste considerations and the potential to cause corrosion in the distribution system. This document proposes to maintain the AO for chloride at ≤ 250 mg/L based on the same considerations of taste and corrosion.

- sulphate, developed in 1994, established an AO of ≤ 500 mg/L based on taste. This document proposes to maintain the AO for sulphate at ≤ 500 mg/L based on the same consideration of taste.

- TDS, developed in 1994, established an AO of ≤ 500 mg/L based on excessive scaling in water pipes, heaters and appliances. The document proposes to maintain the AO for TDS at ≤ 500 mg/L based on the same considerations for scaling.

- sulphide, developed in 1992, established an AO of ≤ 0.05 mg/L (50 μg/L) based on taste and odour. This document proposes to maintain the AO for sulphide at ≤ 0.05 mg/L based on the same considerations of taste and odour.

This document is available for a 60-day public consultation period. Please send comments (with rationale, where required) to Health Canada via email at:

All comments must be received before May 31, 2024. Comments received as part of this consultation will be shared with members of the Federal-Provincial-Territorial Committee on Drinking Water (CDW), along with the name and affiliation of their author. Authors who do not want their name and affiliation shared with CDW members should provide a statement to this effect along with their comments.

This guideline technical document may be revised following the evaluation of comments received, and a drinking water guideline will be established, if required. This document should be considered as a draft for comment only.

Proposed guideline values

Aesthetic objectives (AOs) are proposed for the following parameters:

- chloride ≤ 250 mg/L

- sulphate ≤ 500 mg/L

- total dissolved solids (TDS) ≤ 500 mg/L

- hydrogen sulphide ≤ 0.05 mg/L in drinking water

Contents

- Executive summary

- 1.0 Exposure consideration

- 2.0 Health Considerations

- 3.0 Derivation of the health-based value (HBV)

- 4.0 Analytical considerations

- 5.0 Treatment considerations

- 6.0 Management strategies

- 7.0 International considerations

- 8.0 Rationale for aesthetic objectives

- 9.0 References

- Appendix A: Abbreviations

- Appendix B: Provincial data tables

- Appendix C: Health Canada Drinking Water Survey Data

- Appendix D: Summary of total hardness removal for residential scale technologies

- Appendix E: Intake of sodium as a result of water softener use, by hardness level

Executive summary

This guideline technical document was prepared in collaboration with the Federal-Provincial-Territorial Committee on Drinking Water (CDW). It consolidates and updates all relevant information for the seven parameters: calcium, magnesium, hardness, chloride, sulphate, TDS and hydrogen sulphide.

Exposure

Calcium, magnesium, hardness, chloride, sulphate, TDS and hydrogen sulphide occur naturally and are found in all Canadian waters. They are most significant in groundwater aquifers.

Health effects

Calcium, magnesium, chloride and sulphate are essential elements.

Studies in humans have found that intake of calcium supplements may increase the risk of kidney stone formation. Excess calcium intake and hypercalcemia from foods and water alone are unlikely. A health-based value of 300 mg/L is proposed for calcium based on an elevated risk of kidney stone formation.

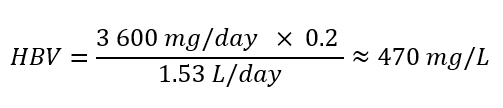

Studies in humans have found that increased intake of chloride, as sodium chloride, may elevate blood pressure. A health-based value of 470 mg/L is proposed for chloride based on an elevated risk of elevated blood pressure.

Currently, there is insufficient evidence to support the need for health-based values for magnesium, hardness, sulphate, TDS or hydrogen sulphide.

Aesthetic considerations

Calcium, magnesium, hardness, chloride, sulphate, TDS and hydrogen sulphide are considered to have operational significance for drinking water utilities and residential water consumers.

Increased chloride levels can result in an objectionable water taste when it is in the presence of sodium, calcium, potassium and magnesium. Sulphate also has a taste threshold, with moderate concentrations more acceptable to most consumers from a taste perspective. Hydrogen sulphide is predominantly an issue due to its offensive rotten egg odour and its low odour threshold. High levels of TDS can lead to excessive scaling in water pipes, heaters, boilers and home appliances. Concerns regarding the presence of these substances in drinking water are often related to consumer complaints.

The AOs for chloride (≤ 250 mg/L), sulphate (≤ 500 mg/L), TDS (≤ 500 mg/L) and hydrogen sulphide (≤ 0.05 mg/L) are intended to minimize the occurrence of complaints based on unacceptable taste, odour or excessive scaling, and to improve consumer confidence in drinking water quality. The AOs are primarily based on taste and odour acceptance, which varies based on source water, local conditions, habituation, pH and water temperature.

Analytical and treatment considerations

The development of a drinking water guideline takes into consideration the ability to measure the contaminant and to remove it from drinking water supplies. Several analytical methods are available for measuring all of the operational parameters well below their respective proposed AO values.

At the municipal level, treatment technologies that are available to decrease the levels of calcium, magnesium, hardness, chloride, sulphate, TDS and hydrogen sulphide in drinking water include softening, membrane filtration, ion exchange (IX) and aeration. Most well-operated and optimized treatment plants can achieve concentrations in the treated water below the proposed AO for each parameter. Prior to full-scale implementation, bench- and/or pilot-scale studies should be conducted using source water to ensure sufficient removal and to optimize performance.

In cases where removal of these substances is desired at a small-system or household level, for example, a private well, a residential drinking water treatment unit may be an option. Several treatment technologies can be effective for reducing these substances at a residential scale, for example, a small system or in a household whose drinking water supply is from a private well. Water softeners are the best potential technology for the overall reduction of these operational parameters. When using a residential drinking water treatment unit, it is important to take samples of water entering and leaving the treatment unit and send them to an accredited laboratory for analysis, to ensure that adequate iron removal is achieved. Routine operation and maintenance of treatment units, including replacement of filter components, should be conducted according to manufacturer specifications.

Individuals on sodium-restricted diets or needing to limit their exposure to sodium should be aware that residential water softening systems will increase the concentration of sodium in the treated water. In this case, it is recommended that a portion of the water most frequently consumed ( from the kitchen tap) bypass the softener altogether to avoid excessive salt intake. Generally, children under 8 years of age should not drink water containing sodium from a water softener as they may exceed the recommended upper limit of 1.5–1.9 mg of sodium/day.

Application of the guidelines

Note that specific guidance related to implementing drinking water guidelines should be obtained from the appropriate drinking water authority.

This document is intended to update, consolidate and replace the current guideline technical documents for seven parameters: calcium, magnesium, hardness, chloride, sulphate, total dissolved solids and hydrogen sulphide. For the purpose of this guideline document, these seven parameters are referred to as operational parameters.

All water utilities should implement a risk management approach such as the source-to-tap or water safety plan approach to ensure water safety. These approaches require a system assessment to characterize the source water, describe the treatment barriers that prevent or reduce contamination, identify the conditions that can result in contamination and implement control measures. Operational monitoring is then established and operational and management protocols such as standard operating procedures, corrective actions and incident responses are instituted. Other protocols are also implemented to validate the water safety plan, such as record keeping and consumer satisfaction are also implemented. Operator training is also required to ensure the effectiveness of the water safety plan at all times.

Considering that the levels of these operational parameters can vary significantly in source water, within treatment plants and in distribution systems, monitoring programs should be system-specific to enable utilities to have a good understanding of their water quality from source to tap. Monitoring programs should be designed based on risk factors that contribute to the likelihood that calcium and chloride may be elevated within the drinking water system. These factors may include source water chemistry and use of road salt, among others. The locations, frequency and types of samples that should be collected will differ from one system to the next, depending on the desired objective and site-specific considerations. Suggested monitoring details are provided in section 6.0, Management strategies.

1.0 Exposure consideration

Calcium, magnesium, hardness, chloride, sulphate, total dissolved solids (TDS) and hydrogen sulphide are naturally co-occurring in most Canadian waters but their presence is most significant in groundwater aquifers. These parameters are considered to have operational and aesthetic significance, particularly for groundwater systems and private well owners, and addressing them will help ensure good quality, palatable drinking water.

Water in nature comes into contact with minerals, salts, metals and vegetation – including molecular and colloidal matter – which are then dissolved into the water. The measure of all these dissolved combined substances in water is known as TDS. TDS comprises mostly ions such as calcium, magnesium, sodium, bicarbonates, chloride and sulphate. Hydrogen sulphide is produced from the breakdown of organic matter in the absence of oxygen, but may also be reduced directly from sulphate in the presence of sulphate-reducing bacteria. It is widely present in sediments and water, as well as in biological wastes.

Since some of these parameters are typically measured, handled and monitored together, they are discussed together in the document as follows:

- Calcium and magnesium: these are the primary contributing cations for water hardness.

- Chloride and sulphate: these are primarily related to aesthetic concerns but there are also operational considerations related to corrosion.

- TDS: these are a main determinant in the taste of water and people’s acceptance. High TDS are also of operational concern due to the formation of scale deposits.

- Hydrogen sulphide: has an offensive rotten egg odour that is often the primary reason for its removal during the water treatment process.

1.1 Identity, uses and sources in the environment

The parameters discussed in this guideline document are major cations and anions that are naturally occurring in Canadian waters and are most significant in groundwater aquifers.

1.1.1 Calcium, magnesium and hardness

Water hardness is defined as the sum of all multivalent cations in a solution. The principal hardness-causing ions are calcium and magnesium. Although hardness is caused by calcium and magnesium and a variety of other metals, the simple definition of water hardness is the amount of dissolved calcium and magnesium in the water. Strontium, iron, barium and manganese ions also contribute to the overall hardness but are generally present in lower concentrations. From a consumer perspective, hard water may be better observed as a reduced ability of water to react with soap. Hard water requires a considerable amount of soap to produce a lather, and it also causes scaling of hot water pipes, boilers and other household appliances (Davis, 2010; Crittenden et al., 2012).

Groundwater is generally harder than surface water, is rich in carbonic acid and dissolved oxygen, and usually has a high solvating power. Longer residence times within calcium-rich formations (such as, calcite, gypsum and dolomite) can lead to hardness levels as high as several thousand milligrams per litre. Residence times and solubility can vary seasonally in some aquifers.

Ferromagnesian mineral igneous rocks and magnesium carbonates in sedimentary rocks are generally considered to be the principal sources of magnesium in natural waters. The principal natural sources of hardness in water are sedimentary rocks, seepage and runoff from soils.

| Property | Calcium | Magnesium |

|---|---|---|

| CAS RN | 7440-70-2 | 7439-95-4 |

| Molecular formula | Ca | Mg |

| Molecular Weight (g/mol) | 40.078 | 24.3050 |

| Melting point | 842°C, 1115 K | 648.8°C, 921.8K |

| Boiling Point | 1484°C, 1757 K | 1090°C, 1363K |

| Density at room temp (g•cm-3) | 1.55 | 1.738 |

Calcium is the fifth most abundant natural element and is the primary source of hardness. Some of the common forms of calcium are calcium carbonate (CaCO3), gypsum (CaSO4·2H2O), anhydrite (CaSO4) and fluorite (CaF2) (Yaroshevsky, 2006; Crittenden et al., 2012). Surface water generally contains lower concentrations of calcium than groundwater. Notably, some areas of the country have observed decreasing calcium concentrations in surface water sources. There have been reductions in calcium in several boreal lakes with already low levels of calcium when comparing concentrations observed in the 1980s versus the 2000s (Jeziorski et al., 2008). This is thought to be due to reduced calcium contributions to water bodies from soil as acidic precipitation has been greatly reduced over this time period. The increased prevalence of invasive zebra mussels is also thought to cause decreased calcium concentrations in some surface water sources (Chapra et al., 2012).

Magnesium is the eighth most abundant natural element and is commonly found in such minerals as magnesite, dolomite, olivine, serpentine, talc and asbestos. It is present in all natural waters and is a major contributor to water hardness. Water from areas rich in magnesium-containing rocks may contain magnesium in the range of 10 mg/L to 50 mg/L. The sulphates and chlorides of magnesium are very soluble, and water in contact with such deposits may contain several hundred milligrams of magnesium per litre. Industrial effluents may contain similarly high levels of magnesium. Calcium and magnesium may also be introduced to a water supply intentionally as part of water treatment. Where hardness is extremely low (such as soft water) in a water system, the addition of calcium or magnesium to the water may be needed to decrease corrosion effects downstream. Sources of hardness may include a limestone or pellet contactor, or direct injection of a solution or slurry consisting of calcium or magnesium hydroxides.

The degree of hardness of drinking water may be classified in terms of its CaCO3 concentration as soft, medium hard (or moderately hard), hard and very hard. Different ranges to characterize these classifications are encountered in the literature (Table 2).

| Extremely soft (mg/L ) |

Soft (mg/L ) |

Medium hard or Moderately hard (mg/L) |

Hard (mg/L) |

Very hard (mg/L) |

Reference |

|---|---|---|---|---|---|

| 0–50 | 50–100 | 100–150 | 150–300 | > 300 | Davis (2010) |

| N/A | 0–75 | 75–150 | 150–300 | > 300 | AWWA (2005) |

| N/A | 0 to < 50 | 50 to < 100 | 100 to < 150 | > 150 | Crittenden et al. (2012) |

| N/A | 0 to < 60 | 60 to < 120 | 120 < 180 | > 180 | As cited in Crittenden et al. (2012) |

| N/A | 0–60 | 61–120 | 121–180 | > 180 | USGS (2018) |

| N/A | N/A | 60–120 | 120–180 | > 180 | Droste (2019) |

|

|||||

Due to the relationship between calcium, magnesium and hardness, practitioners often convert the concentrations of calcium and magnesium into their equivalents as CaCO3. This is the traditional unit of measure for hardness. The calcium concentration is multiplied by 2.5 (based on the molar ratio) to convert it to a unit of CaCO3 mg/L. Similarly, the magnesium concentration is multiplied by 4.1 (based on the molar ratio) to provide a result in mg/L as CaCO3.

Public acceptance of hardness varies considerably according to the local conditions, tolerance, pH and the temperature of the water, and consumers may get used to higher levels of hardness in their water. Water supplies with a hardness greater than 200 mg/L are considered poor but have been tolerated by consumers; those in excess of 500 mg/L are unacceptable for many domestic purposes and may require softening. The palatability of the water also depends on the ionic makeup of the water being consumed.

Water softening by sodium ion exchange (IX) may introduce undesirably high quantities of sodium into drinking water. As such, it is recommended that a portion of the water most frequently consumed (such as the kitchen tap) bypass the softener altogether to avoid excessive salt intake.

The aesthetic concerns for water hardness come from the tendency of hardness ions to precipitate out of solution (primarily as hydroxide and carbonate salts) and form scale on the inside of hot water–bearing pipes and water heating appliances. This is generally related to pH and temperature. These two characteristics change the solubility of calcium and magnesium and may result in oversaturation of a solution, resulting in precipitation of scale. The precipitated hardness may lead to particles or turbidity that are visible to the naked eye. Depending on the primary chemical element responsible for contributing to hardness, consumers may also note discoloration of the water. The precipitation of calcium and magnesium scales are generally white in colour.

Although hardness is caused by multivalent cations, it is often discussed in terms of carbonate and non-carbonate hardness. Carbonate hardness refers to the amount of carbonates (CO32-) and bicarbonates (HCO3-) that can be precipitated out of solution with heating. This type of hardness is responsible for the scale that may be deposited in hot water pipes and kettles. Non-carbonate hardness is caused by the association of the hardness causing cations with sulphates (SO4-), chlorides (Cl-) and nitrates (NO3-), as well as the salts of calcium and magnesium such as calcium sulphate (CaSO4), calcium chloride (CaCl2), magnesium chloride (MgCl2) and magnesium sulphate (MgSO4) (AWWA, 2016). Non-carbonate hardness is more readily kept in solution, but still participates in the inhibition of soaping functions (Crittenden et al., 2012).

Utilities may determine the amount of CaCO3 that will precipitate calcium using the calcium carbonate precipitation potential (CCPP) to predict the potential for scaling (Schock and Lytle, 2011; Tang et al., 2021). It can be calculated by a variety of computer programs or spreadsheet-based applications (RTW, 2008; AWWA, 2017; APHA et al, 2018).

In areas with hard water, household pipes can become clogged with scale (Coleman, 1976). Hard waters can also cause incrustations on kitchen utensils and increase soap consumption. Hard water is thus both a nuisance and an economic burden to the consumer.

Hard water is generally less corrosive than soft water (Letterman and American Water Works Association, 1999). It has been suggested that a hardness level of 80 mg/L to 100 mg/L as CaCO3 provides an acceptable balance between corrosion and incrustation (Bean, 1968). Other taste thresholds for minor hardness constituents are discussed in the drinking water guidelines for manganese and iron (Health Canada, 2019, 2023).

Alkalinity controls the buffer intensity of most water systems. It is closely linked to hardness and is expressed in milligrams of CaCO3 per litre (mg/L as CaCO3). As the alkalinity of most Canadian surface waters is due to the presence of carbonates and bicarbonates, their alkalinity is similar to their hardness (Thomas, 1953).

Hardness can also be measured as grain per gallon, where a grain per gallon of hardness is equivalent to 17.1 mg CaCO3/L of hardness (Appendix E).

1.1.2 Chloride and sulphate

Chloride is widely distributed in nature, generally as sodium (NaCl) and potassium (KCl) salts; it constitutes approximately 0.05% of the lithosphere. By far the greatest amount of chloride found in the environment is in the oceans. Underground salt deposits have been found in most Canadian provinces. Bedded deposits occur in southwestern Ontario, Saskatchewan and Alberta; dome deposits are found in Nova Scotia, New Brunswick, Ontario, Manitoba, Saskatchewan and Alberta.

Chapra et al. (2012) describe the long-term trends of major ions in the Great Lakes system. They note that minimum chloride concentrations in Lake Ontario and Lake Erie were reached in approximately 1995 and 1985, respectively, with a slow rise in subsequent years. The Geological Survey of Canada (2014) noted that chloride levels have been found to increase in urban municipal wells and that the shallow groundwater near highways in Toronto have been found to have chloride levels as high as 14 000 mg/L due to the use of road salt during winter. The upper Great Lakes have all shown steady increases in chloride concentrations since the 1960s. The trend towards higher chloride levels has been noted across North America (Kaushal et al., 2018).

Sulphate occurs naturally in numerous minerals, including barite (BaSO4), epsomite (MgSO4 ·7H2O) and gypsum (CaSO4·2H2O). Sulphates are discharged into the aquatic environment in wastes from industries that use sulphates and sulphuric acid, such as mining and smelting operations, kraft pulp and paper mills, textile mills and tanneries. Aluminum sulphate (alum) is used as a coagulant in the treatment of drinking water, and copper sulphate has been used for the control of blue-green algae/cyanobacteria in both raw water and public water supplies in the United States. Sulphate concentrations are slowly decreasing in Lake Erie and Lake Ontario as a result of reduced impacts from acid rain caused by industrial activities. In the other Great Lakes – Lakes Michigan, Huron and Superior – concentrations of sulphate have remained stable over the past 50 years (Chapra et al., 2012).

Atmospheric sulphur dioxide (SO2), formed by the combustion of fossil fuels and by the metallurgical roasting process, may also contribute to the sulphate content of surface waters. Sulphates or sulphuric acid products are also used in the manufacture of numerous chemicals, dyes, glass, paper, soaps, textiles, fungicides, insecticides, astringents and emetics. They are also used in the mining, pulping, metal and plating industries, in sewage treatment and in leather processing.

| Property | Chloride | Interpretation | Sulphate | Interpretation |

|---|---|---|---|---|

| CAS RN | 16887-00-6 | N/A | 14808-79-8 | N/A |

| Molecular formula | Cl- | N/A | SO4-2 | N/A |

| Molecular Weight (g/mol) | 35.45 | N/A | 96.064 | N/A |

| Melting point | 101°C | N/A | N/A | N/A |

| Boiling Point | N/A | N/A | N/A | N/A |

| Density at room temp | N/A | N/A | N/A | N/A |

| Solubility | 6.3 mg/mL at 25°C | High solubility | N/A | N/A |

|

||||

Studies have shown that both chloride and sulphate have an impact on corrosion in the distribution system, especially with metallic pipe and components. The chloride-to-sulphate mass ratio (CSMR) is used as an indicator of galvanic corrosion potential, particularly for lead. Dudi and Edwards (2004) conclusively demonstrated that a chloride-to-sulphate mass ratio greater than 0.58 increased lead leaching from brass due to galvanic connections. Further information on corrosion control is available (Health Canada, 2022a). The Larson Index (the ratio of the sum of chloride and sulphate to bicarbonate) is also important, with a higher ratio indicating water that is more corrosive water to iron (Larson and Skold, 1958). Sulphate has also been identified as a nutrient that has a role in microbial growth, either in serving as a fuel for microorganisms or by consuming disinfectant residuals in the distribution system. For further information, refer to the Guidance on Monitoring the Biological Stability of Drinking Water in Distribution Systems (Health Canada, 2022b).

Chlorides and sulphates can play a role in water hardness, where they may contribute to the stability of non-carbonate hardness. Non-carbonate hardness involves salts of calcium chloride, calcium sulphate, magnesium chloride or magnesium sulphate, which present as hardness when titrated with ethylene diaminetetra acetic acid (EDTA) but are not considered scale forming. They will not precipitate when heated but still cause reduced lathering of soap. Other minor contributions of non-carbonate hardness include chloride or sulphate salts of barium or strontium.

Higher concentrations of chloride are most often present in drinking water derived from groundwater sources. The presence of chloride in drinking water sources can be attributed to the dissolution of salt deposits, salting of highways to control ice and snow, effluents from chemical industries, oil well operations, sewage, irrigation drainage, refuse leachates, volcanic emanations, sea spray and seawater intrusion in coastal areas. Each of these sources may result in local contamination of surface water and groundwater. Chloride ions are highly mobile and are eventually transported into closed basins or to the oceans.

Sodium chloride is widely used in the production of industrial chemicals such as caustic soda (sodium hydroxide), chlorine, soda ash (sodium carbonate), sodium chlorite, sodium bicarbonate and sodium hypochlorite. Sodium chloride and, to a lesser extent, calcium chloride (CaCl2) are used for snow and ice control in Canada. Annual usage is estimated to be about 5 million tonnes of salt during winter months (Environment and Climate Change Canada, 2022). Much of this road-applied salt directly enters local surface water bodies during the spring melt (Pieper et al., 2018). However, some salt has been shown to accumulate in soils and subsurface formations. This leads to delayed release to the surrounding aquatic environment in subsequent seasons and causes elevated sodium and chloride levels throughout the year (Robinson et al., 2017). Road salt contamination in drinking water is generally limited to wells near paved roads and areas with heavy applications and is affected by the topography of the area (Geological Survey of Canada, 2014).

Sulphate salts of sodium, potassium and magnesium are all soluble in water, whereas calcium and barium sulphates and the heavy metal sulphates are not. Sulphates occur naturally in numerous minerals, including barite (BaSO4), epsomite (MgSO4·7H2O) and gypsum (CaSO4·2H2O). The reversible interconversion of sulphate and sulphide in the natural environment is known as the “sulphur cycle.” Sulphates are discharged into the aquatic environment in wastes from industries that use sulphates and sulphuric acid, such as mining and smelting operations, kraft pulp and paper mills, textile mills and tanneries.

1.1.3 Total dissolved solids (TDS)

TDS are a measure of all dissolved substances that are found in a water sample, including all ionic, molecular and colloidal matter. The primary ions contributing to TDS include calcium, magnesium, sodium, chloride and sulphate.

TDS in water supplies originate from natural sources, sewage, urban and agricultural runoff, and industrial wastewater (Droste, 1997). The concentration of TDS is influenced by the solubility of the soil and rock and the contact time, which can vary seasonally in some aquifers. In Canada, salts used for road de-icing can contribute significantly to the TDS loading of water supplies (Chapra et al., 2012).

Water containing less than 1000 mg/L of TDS is considered freshwater while water with TDS levels between 1000 mg/L and 10 000 mg/L is considered brackish water (Crittenden et al., 2012). Concentrations of TDS in water vary owing to different mineral solubility in geological regions. The concentration of TDS in water in contact with granite, siliceous sand, well-leached soil or other relatively insoluble materials may be below 30 mg/L.

TDS is usually associated with high concentrations of ions that increase the conductivity of water and may affect the formation of a protective film (Letterman and American Water Works Association, 1999). When hardness is the main contributor to TDS, the water may be corrosive toward copper. When sulphate and chloride are the main anionic contributor to TDS, the water may be corrosive to iron-based materials (Letterman and American Water Works Association, 1999). High TDS may also lead to scale deposits in distribution systems and home appliances (Van der Aa., 2003).

1.1.4 Hydrogen sulphide

Hydrogen sulphide (H2S) is a naturally occurring gas produced from the breakdown of organic matter in the absence of oxygen and may also be formed by the direct reduction of sulphate by sulphate-reducing bacteria. It is widely present in sediments and water, as well as in biological wastes.

It has been estimated that natural sources account for 60% to 90% of the hydrogen sulphide in the atmosphere globally (U.S. EPA, 1993a; Watts, 2000). Hydrogen sulphide is produced naturally through non-specific and anaerobic bacterial reduction of sulphates and sulphur-containing organic compounds, such as proteins and amino acids (Hill, 1973). It is found naturally in crude petroleum, natural gas, volcanic gases and hot springs and is released primarily as a gas. Hydrogen sulphide is found naturally in a variety of environmental media, including anaerobic aquatic sediments and groundwater, owing primarily to the bacterial reduction of other forms of sulphur.

| Property | Hydrogen sulphide | Interpretation |

|---|---|---|

| CAS RN | 7783-06-4 | N/A |

| Molecular formula | H2S | N/A |

| Molecular weight (g/mol) | 35.45 | N/A |

| Melting point (°C) | -85.49 | N/A |

| Boiling point (°C) | -60.33 | N/A |

| Density at room temp | 1.5392 g/L at 0°C at 760 mm Hg; | N/A |

| Solubility | 3980 mg/L at 20°C | High solubility |

|

||

Hydrogen sulphide can be released as a result of agricultural activities or industrial processes. These include releases as a by-product from petroleum sector activities since natural gas and gases associated with crude oil contain hydrogen sulphide at levels varying from trace amounts to 70%–80% by volume (Pouliquen et al., 1989; Environment Canada, 2004a). Hydrogen sulphide can be generated during hydraulic fracturing (Kahrilas et al., 2015; Marriott et al., 2016). Other anthropogenic sources include liquid manure storage (Blunden and Aneja, 2008; Kim et al., 2008), kraft pulp and paper mills (Teschke et al., 1999; IPCS, 2003; ATSDR, 2006; Janssen et al., 2009), landfills (IPCS, 2003; ATSDR, 2006; Kim, 2006), decomposition of organic waste from wastewater treatment (Muezzinoglu, 2003) and other industrial processes such as metal refining (OMOE, 2007; NPRI, 2023). Releases to the environment are primarily in the form of emissions to ambient air, although sulphides (including hydrogen sulphide) may also be released to water under specific environmental conditions.

Hydrogen sulphide can accelerate corrosion by reacting with metal ions but may not be evident for months. It can react with iron, steel copper and galvanized piping to form black water, even when oxygen is absent (Schock and Lytle, 2011). Studies have shown that hydrogen sulphide plays a role in the degradation of concrete and asbestos-cement pipe in some water (LeRoy et al., 1996; Vollertsen et al., 2008; Correa et al., 2010; Radlinksi and Wolf, 2016).

1.2 Exposure

Canadian water monitoring data were obtained from the provinces (municipal and non-municipal supplies). No data were provided by the territories. Data were from a variety of water supplies in Canada, including surface water and groundwater, as well as treated and distributed water where monitoring occurred (British Columbia Ministry of Health, 2021; Ontario Ministry of the Environment, Conservation and Parks, 2021; Manitoba Sustainable Development, 2021; Ministère de l’Environnement et de la Lutte contre les changements climatiques, 2021; Nova Scotia Environment, 2021; Saskatchewan Water Security Agency, 2021; PEI Department of Communities, Land and Environment, 2021; New Brunswick Department of Health, 2021; Newfoundland and Labrador Municipal Affairs and Environment, 2021). The exposure data provided reflect different detection limits (DL) of accredited laboratories used within and among the jurisdictions, as well as their respective monitoring programs. As a result, the statistical analysis of exposure data provides only a limited picture.

The concentrations of these parameters in raw groundwater water are typically higher than in raw surface water. The concentrations of raw groundwater are presented in Tables 5 and 6 and the full tables for each parameter in different water types are presented in Appendix B.

In general, higher concentration of calcium, magnesium, hardness, chloride, sulphate and TDS were found in raw groundwater when compared with raw surface water. However, it should be noted that in Saskatchewan, the raw surface water generally had a higher level than the raw groundwater of calcium, magnesium, hardness, sulphate and TDS. Private wells showed trends similar to those of raw water from public utilities. Fluctuations between treated water and distributed water were observed for several parameters.

The median values for calcium and chloride were generally below the health-based values (HBV) determined for these substances of 300 mg/L and of 470 mg/L respectively (see section 3.0). However, in most provinces (British Columbia, Manitoba, Newfoundland, Nova Scotia, Ontario, Prince Edward Island, Quebec and Saskatchewan), the maximum value recorded for calcium exceeded the HBV. For chloride, the maximum value observed in each province exceeded the HBV. Limited monitoring data were provided for hydrogen sulphide.

| Provinces | Calcium (mg/L) |

Magnesium (mg/L) |

Hardness (mg/L as CaCO3) |

Chloride (mg/L) |

Sulphate (mg/L) |

TDS (mg/L) |

Sulphide (mg/L) |

|---|---|---|---|---|---|---|---|

| British Columbia | 59.1 | 13.2 | 215 | 6.3 | 29.7 | N/A | N/A |

| Manitoba | 73.7 | 40 | 368 | 18.4 | 60.4 | 521 | N/A |

| New Brunswick | 27.4 | 3.9 | 92 | 35.6 | 15 | 131 | 0.05 |

| Newfoundland | 27.5 | 6 | 96 | 25.5 | 8 | 181 | N/A |

| Nova Scotia | 33.8 | 5.8 | 120 | 30 | 13 | 202 | 0.05 |

| Ontario | 85.7 | 25.3 | 320 | 70.3 | 34 | 448 | 0.03 |

| Prince Edward Island | 36.6 | 12.5 | 159 | 18.5 | 7.8 | 208 | N/A |

| Saskatchewan | 128 | 50.5 | 532 | 13.2 | 320 | 1210 | N/A |

|

|||||||

| Provinces | Calcium (mg/L) |

Magnesium (mg/L) |

Hardness (mg/L as CaCO3) |

Chloride (mg/L) |

Sulphate (mg/L) |

TDS (mg/L) |

Sulphide (mg/L) |

|---|---|---|---|---|---|---|---|

| British Columbia | 59.1 | 12.9 | 234.5 | 6.4 | 32.6 | N/A | N/A |

| Nova Scotia | 27 | 4 | 98 | 21 | 11 | 180 | N/A |

| Prince Edward Island | 32.5 | 13.1 | 136.4 | 14.8 | 6.4 | 214 | N/A |

| Quebec | 44.3 | 10.9 | 166 | 91.2 | 40.7 | 684 | 0.075 |

|

|||||||

Health Canada has completed several targeted drinking water surveys that included measurements of these operational parameters (Appendix C; Health Canada, 2022c).

- Data from the 2009–2010 National Drinking Water Survey conducted by Health Canada can be found in Appendix C.1.

- In 2007, a survey targeting water plants using water sources with elevated bromide was conducted. In this survey, data on calcium, magnesium, hardness, chloride, sulphate and TDS were also collected and the results can be found in Appendix C.2.

- In 2012–2013, a targeted national survey of water treatment plants with high sodium and naturally present ammonium/chloramines used was conducted. In this survey, data on calcium, magnesium, hardness, chloride, sulphate and TDS were also collected and the results can be found in Appendix C.3.

Hydrogeological mapping on the concentration of calcium, magnesium, hardness, chloride, sulphate and TDS in surface and groundwater are available (Department of Fisheries and the Environment, 1978a, 1978b, 1978c). A detailed overview of Canada’s groundwater is available (Geological Survey of Canada, 2014).

2.0 Health Considerations

2.1 Calcium, magnesium and hardness

2.1.1 Essentiality

Magnesium and calcium, the two predominant cations that make up water hardness, are essential minerals and beneficial to human health in numerous ways (IOM, 1997, 2011; Silva et al., 2019). Other essential minerals that contribute to water hardness include copper, iron, manganese and zinc (Silva et al., 2019; Water Resources, 2019). Aluminum, barium, cadmium and lead are also part of hardness but are non-essential elements (Exley, 2013; Chellan and Sadler, 2015; Water Resources, 2019). Strontium is likely a non-essential trace element (Bain et al., 2009; Zhao et al., 2015).

Magnesium is a cofactor for more than 300 enzymatic reactions and plays an essential role in electrolytic homeostasis, for the synthesis of carbohydrates, lipids, nucleic acids and proteins, as well as for specific actions in various organs such as the neuromuscular or cardiovascular systems (Wacker and Parisi, 1968; Cowan, 2002; Romani, 2013; EFSA, 2015a).

Calcium plays an important role in the formation and resorption of bone, in mediating vascular contraction and vasodilation, muscle function, nerve transmission, intracellular signalling, blood clotting and hormonal secretion (Campbell, 1990; Brown, 1991; Peacock, 2010; IOM, 2011; EFSA, 2015b).

Magnesium and calcium deficiency may be detrimental to human health, while increasing intake generally results in health benefits. Magnesium deficiency has been reported to be linked to an increased risk of cardiovascular disease, hypertension, diabetes, osteoporosis, cancers, and renal and gastrointestinal dysfunctions (Tucker et al., 1999; Anastassopoulou and Theophanides, 2002; Catling et al., 2008; Rude et al., 2009; Dong et al., 2011; Rodríguez-Morán et al., 2011; Kass et al., 2012; Del Gobbo et al., 2013; EFSA, 2015a; Zhang et al., 2016; Rapant et al., 2019). Hypocalcemia and hypokalemia may also occur, which can lead to neurological or cardiac symptoms when it is associated with marked hypomagnesemia (< 0.5 mmol/L) (EFSA, 2015a). Loss of appetite, fatigue, muscle spasm and weakness may be signs of magnesium deficiency (Bowman and Russell, 2006).

If the dietary intake of calcium is insufficient to meet physiological requirements, calcium is resorbed from the skeleton to maintain blood concentrations within the range required for normal cellular and tissue functions. This may lead to rickets, osteomalacia, osteoporosis and increased risk of fractures (EFSA, 2015b). Inadequate intake of calcium has also been associated with increased risks of kidney stones, colorectal cancer, hypertension and stroke, coronary artery disease, insulin resistance and obesity (WHO, 2011).

2.1.2 Beneficial effects

It has been suggested that consuming hard water is protective against osteoporosis, decreased cognitive function in the elderly, decreased birth weight, various cancers and diabetes mellitus (Burton and Comhill, 1977; Yang et al., 1997, 1998, 1999, 2000a; Rosborg and Kozisek, 2020). Higher magnesium and/or calcium intake has been reported to offer a protective effect against cardiovascular disease, stroke, pre-eclampsia in pregnant women, high blood pressure and metabolic syndrome (Melles and Kiss, 1992; Catling et al., 2008; Nie et al., 2013; Poursafa et al., 2014; Chen et al., 2015; Khan et al., 2015; Moore-Schiltz et al., 2015; Anderson et al., 2016; Hofmeyr et al., 2018; Cormick et al., 2022).

Increasing magnesium and calcium intake has also been suggested as protective against various cancers, including colorectal, prostate, breast, ovarian and liver (Yang et al., 2000a, 2000b; Kesse et al., 2006; Chen et al., 2010; Keum et al., 2014; Aune et al., 2015; Bonovas et al., 2016; Hidayat et al., 2016; Song et al., 2017; Wesselink et al., 2020; Zhong et al., 2020; Shah et al., 2021). Increasing calcium intake has a positive effect on bone health, increasing bone mineral density, reducing circulating parathyroid hormone levels and bone turnover markers, and reducing the risk of fractures (Guillemant et al., 2000; Meunier et al., 2005; Silk et al., 2015; Tai et al., 2015; Weaver et al., 2016; Liu et al., 2020).

2.1.3 Adverse effects

Hardness, magnesium and calcium have low potential for toxicity to humans through drinking water. Adverse effects associated with excess intake of magnesium, calcium and/or hardness at elevated levels are seldom reported (WHO, 2009, 2011; Cotruvo et al., 2017). No adverse effects have been associated with the ingestion of magnesium from food sources, while supplementation of magnesium in excess of the daily recommended allowance may lead to adverse symptoms such as osmotic diarrhea (IOM, 1997; WHO, 2009, 2011). Water with very high magnesium levels, together with high sulphate (> 400 mg/L combined), may cause transient diarrhea (Rosborg and Kozisek, 2020). Water with very high levels of magnesium (together with high level of TDS) may increase the risk of renal and other types of stones and arthritis problems (Kozisek, 2020). Symptoms of excess magnesium may include change in mental status, diarrhea, loss of appetite, muscle weakness, difficulty breathing, low blood pressure and irregular heartbeat. However, adverse effects associated with magnesium intake are most likely due to excess magnesium from supplements and do not generally happen to people with normal kidney function (WHO 2009, 2011; Rosborg and Kozisek, 2020). Similarly, excess calcium intake from foods alone is difficult or impossible to achieve, and hypercalcemia is unlikely to occur with high intake of calcium from the diet alone due to a tightly regulated intestinal absorption mechanism, where excess calcium is excreted by the kidneys (WHO, 2009, 2011; IOM, 2011). Excess calcium intake and hypercalcemia may be caused by high-dose calcium supplements, especially when accompanied by vitamin D supplements, as these can increase calcium absorption (Aloia et al., 2014; EFSA, 2015b). Intake of calcium supplements above the Tolerable Upper Intake Level (UL) (1 000 mg/day to 3 000 mg/day dependent on the life stage) increases the risk of hypercalcemia, hypercalciuria, vascular and soft tissue calcification, kidney stones, prostate cancer, constipation and interactions with iron and zinc (IOM, 2011). Clinical symptoms of persistent hypercalcemia are fatigue, muscular weakness, anorexia, nausea, vomiting, constipation, tachycardic arrhythmia, vascular and soft tissue calcification, failure to thrive and weight loss (EFSA, 2015b). Hypercalcemia can cause renal insufficiency and vascular and soft tissue calcification, including calcinosis, leading to nephrocalcinosis and kidney stones (IOM, 2011). Dermal exposure to water with high hardness may exacerbate atopic dermatitis (McNally et al., 1998; Miyake et al., 2004; Perkin et al., 2016).

2.1.4 Genotoxicity and carcinogenicity

The mutagenicity of magnesium and calcium was reported to be negligible either with or without S9 mix by Fujii et al. (2016), who completed the Ames test using 0.031 mol/L to 0.25 mol/L Mg(II) and 0.031 mol/L to 0.25 mol/L Ca(II) and Salmonella typhimurium TA100 as the bacterial strain. Sanders et al. (2015) used a comet assay to assess magnesium sulphate genotoxicity on pheochromocytoma (PC-12) cells developed from the rat adrenal medulla. A concentration-dependent increase of DNA damage was evident, with a damage percentage of 8.1% at the 5.01 µg/mL treatment. At 50.01 µg/mL, the percentage of DNA damage was 10.8%.

Ribeiro et al. (2004) investigated the genotoxic potential of calcium hydroxide by the comet assay using mouse lymphoma cells and human fibroblasts cells. The results showed that calcium hydroxide at 20 µg/mL to 80 µg/mL did not promote DNA damage in mammalian cells.

Magnesium appears to play a protective role at the early stages of carcinogenesis but contributes to the proliferation of existing tumours at the later stages (Anastassopoulou and Theophanides, 2002). This is because magnesium is required for cellular proliferation. In neoplastic cells, intracellular magnesium is increased (due to a decrease in binding affinity) and protein and DNA synthesis is promoted (Leidi et al., 2011). Parsons et al. (1974) reported that maintaining plasma-magnesium levels below 0.8 mg/100 mL in patients with existing tumours generally resulted in regression of the tumours.

In a study comprising 142 520 European adult men, a high intake of calcium from dairy products (but not from other foods) was positively associated with prostate cancer risk (Allen et al., 2008). This association with dairy calcium intake may be due to its high correlation with other aspects of dairy food, particularly protein (Allen et al., 2008).

2.2 Chloride and sulphate

2.2.1 Essentiality

Chloride and sulphate are essential elements. Chloride contributes to gastric hydrochloric acid production, electrical activity in general (such as muscular and myocardial activities), the maintenance of blood pressure and renal function, and the volume and electrolyte balance of body fluids (Kataoka, 2021). Chloride also plays a central role in oxygen transport, gas exchange and regulation of renin produced by the juxtaglomerular apparatus (McCallum et al., 2015; Kataoka, 2021). Dietary chloride deficiency is rare. Low intakes of chloride have been described in two breast-fed infants whose mothers’ milk was deficient in chloride, in infants given chloride-deficient formula milks, and among children and adult patients provided with chloride-deficient liquid nutritional products (Asnes et al., 1982; Hill and Bowie, 1983; Rodriguez-Soriano et al., 1983; Kaleita, 1986; Miyahara et al., 2009). In infants, hypochloremia features include growth failure, lethargy, irritability, anorexia, gastrointestinal symptoms, weakness, hypokalemic metabolic alkalosis and hematuria (Gross et al., 1980).

Inorganic sulphate is required for the synthesis of 3’-phosphoadenosine-5’-phosphosulphate (PAPS). PAPS, also known as “active sulphate,” is required for the biosynthesis of many essential sulphur-containing compounds in the body, including chondroitin sulphate, cerebroside sulphate, dermatan sulphate, heparin sulphate, tyrosine-o-sulphate, taurolithocholate sulphate (bile salt) and estrone 3-sulphate. There are hundreds of sulphur-containing compounds in the human body and the body synthesizes all of them, with the exception of the vitamins thiamin and biotin (IOM, 2005). Sulphate requirements are met when intakes meet recommended levels of sulphur amino acids since the major source of inorganic sulphate for humans is due to body protein turnover of the sulphur amino acids methionine and cysteine. Thus, a deficiency of sulphate is not found in humans consuming normal protein intakes with adequate sulphur amino acids (IOM, 2005). However, sulphate deficiency may decrease blood coagulation and blood vessel stability, and low intake from drinking water may contribute to constipation (Rosborg and Kozisek, 2020).

2.2.2 Beneficial effects

Observational studies showed an inverse association (protective effect) between serum chloride and all-cause mortality in hypertensive patients. A serum chloride concentration lower than 100 milliequivalents per litre (mEq/L) was associated with a higher risk of mortality (all-cause, cardiovascular and non-cardiovascular). A 1.5% reduction in all-cause mortality was observed for every 1 mEq/L increase in serum chloride (McCallum et al., 2013). However, the serum chloride concentration cannot be used as a marker for chloride intake, and no studies are available which investigate the association between chloride intake or urinary excretion and cardiovascular disease–related health outcomes (EFSA, 2019).

Sulphate in drinking water decreases the health risks correlated with consumption of heavy metals by acting as an antagonist (Watts, 1997).

2.2.3 Adverse effects

The major adverse effect of increased intake of chloride, as sodium chloride, is elevated blood pressure, which can lead to cardiovascular and renal disease (Luft et al., 1979; MacGregor et al., 1989; Johnson et al., 2001; Sacks et al., 2001; IOM, 2005; EFSA, 2019). Elevation of blood pressure has been shown to rely on the concomitant presence of both sodium and chloride. In normotensive and hypertensive subjects, sodium chloride caused a greater elevation of mean blood pressure than sodium combined with other anions (Kurtz et al., 1987; Shore et al., 1988; Kotchen and Kotchen, 1997; McCallum et al., 2015). On average, blood pressure rises progressively with increased sodium chloride intake (IOM, 2005). In normotensive individuals, significant increases in blood pressure were observed when receiving approximately 7 500–13 900 mg/day sodium chloride (Mascioli et al., 1991; Ganry et al., 1993). Individuals with hypertension, diabetes and chronic kidney disease, as well as older-age individuals and African Americans, tend to be more sensitive to the blood pressure–raising effects of sodium chloride (Tuck et al., 1990; Weinberger, 1993; Morimoto et al., 1997; Morris et al., 1999; Johnson et al., 2001; Vollmer et al., 2001; du Cailar et al., 2002; IOM, 2005). Genetic factors also influence the blood pressure response to sodium chloride (Hunt et al., 1999; Lifton et al., 2002; IOM, 2005). Although rare, acute toxicity may be caused by ingestion of 500–1 000 mg sodium chloride/kg bw (Expert Group on Vitamins and Minerals, 2003). Symptoms include vomiting, ulceration of the gastrointestinal tract, muscle weakness and renal damage, leading to dehydration, metabolic acidosis and severe peripheral and central neural effects. High sodium chloride intakes increase calcium excretion and may increase the risk of kidney stone formation (Castenmiller et al., 1985; McParland et al., 1989; Zarkadas et al., 1989; Sakhaee et al., 1993; Evans et al., 1997; Lietz et al., 1997; Expert Group on Vitamins and Minerals, 2003; Lin et al., 2003; IOM, 2005). However, there is no substantial evidence to suggest a relationship between excess sodium chloride intake and reduced bone mineral density effects (Expert Group on Vitamins and Minerals, 2003). Both sodium and chloride contribute to the worsening of exercise-induced asthma symptoms that are seen after consuming a normal or high sodium chloride diet (Mickleborough et al., 2001). Individuals on sodium-restricted diets or needing to limit their exposure to sodium should be aware that residential softening systems will increase the sodium concentration in the treated water. Appendix E contains information on the intake of sodium as a result of water softener use, by hardness level.

Ingestion of sulphate has been associated with osmotic diarrhea and ulcerative colitis. Osmotic diarrhea is usually short term but may be more severe in infants (Chien et al., 1968; Backer, 2000; IOM, 2005). The extent and nature of the laxative effect are dependent on the specific sulphate salt. Laxative effects are commonly experienced by people consuming drinking water containing sulphate in concentrations > 500 mg/L (Chien et al., 1968; Esteban et al., 1997; Heizer et al., 1997; U.S. EPA, 1999b, 2003a). Laxative effects may occur at lower concentrations when both magnesium and sulphate are present (> 400 mg/L combined) (Rosborg and Kozisek, 2020). Dehydration may also occur if fluid replacement is not maintained (Arnaud, 2003). Humans appear to develop a tolerance to water containing high sulphate concentrations (Schofield and Hsieh 1983). Although the acclimation concentration and rate have not been determined, it generally occurs in adults within one to two weeks (U.S. EPA, 1999a, 2003a).

2.2.4 Genotoxicity and carcinogenicity

Epidemiological data have indicated that there is a positive association between excess sodium chloride intake and risk of gastric cancer (Expert Group on Vitamins and Minerals, 2003; Wang et al., 2009; D’Elia et al., 2014).

Potassium sulphate was not mutagenic at 0.83 mg/plate, 1.66 mg/plate, 3.33 mg/plate and 5.00 mg/plate on TA98 (with and without S9) and TA100 (with S9) strains of Salmonella typhumurim. However, potassium sulphate showed a weak mutagenic effect on the TA100 strain in the absence of S9 but not in a dose-dependent manner (Kayraldiz et al., 2006). Kasprzak et al. (1983) reported that nickel(II) sulphate was not toxic or carcinogenic two years after intramuscular injections of 20 µL doses of 0.2 M nickel(II) sulphate (4.4 µmol/rat) or sodium sulphate (used as a control) every other day for four weeks (rats were injected with 15 x 20 µL doses of 0.2 M nickel(II) sulphate or sodium sulphate). After reviewing toxicity data on sulphate food additives, the United States Environmental Protection Agency (U.S. EPA) Select Committee concluded that there was no evidence that sulphuric acid or ammonium, calcium, potassium and sodium sulphates presented a hazard to public health when they are used at current levels or levels that might reasonably be expected in the future (U.S. EPA, 2003a).

The International Agency for Research on Cancer (IARC) and the U.S. EPA have not reviewed the carcinogenicity of calcium or inorganic sulphate. However, IARC has reviewed the potential carcinogenicity of specific sulphate-containing molecules, such as diethyl sulphate and dimethyl sulphate, and classified them as “probably carcinogenic to humans” (IARC, 2018). It also classified diisopropyl sulphate and cobalt sulphate as “possibly carcinogenic to humans” (IARC, 2018). In 2022, the carcinogenicity of soluble cobalt(II) salts (including cobalt[II] sulphate) was re-evaluated and will be updated as “probably carcinogenic to humans” in Volume 131 of IARC Monographs (Karagas et al., 2022).

2.3 Total dissolved solids (TDS)

Recent data on health effects associated with ingestion of TDS in drinking water are scarce. Recent studies appear to focus on health effects correlated with hardness rather than TDS.

2.3.1 Essentiality

Many ions that make up TDS, such as magnesium, calcium, sodium, chloride and potassium, are essential minerals and consuming adequate levels of these ions is beneficial to human health in numerous ways. Regular consumption of distilled or demineralized water (such as low TDS) for a few weeks or months can lead to deficiencies in calcium, magnesium and/or sodium, leading to extreme fatigue, malaise, nausea, headache, brittleness of nails and hair, pre-eclampsia, twitch, leg and abdominal cramps, metabolic acidosis, higher diuresis and cardiovascular disorders (Kozisek, 2005, 2020).

2.3.2 Beneficial effects

An older study showed a significant negative (protective) correlation between regions supplied with water with high TDS and mortality from cardiovascular diseases in adult men 45 to 64 years old (Schroeder, 1960). However, new data have shown this correlation is likely due to high magnesium or calcium content rather than high TDS (Catling et al., 2008; Del Gobbo et al., 2013; Khan et al., 2015). Other studies reported inverse relationships between TDS concentrations in drinking water and the incidence of cancer and arteriosclerotic heart disease (Schroeder, 1966; Burton and Comhill, 1977). Epidemiological data among Russian populations suggest that high-mineral drinking water may reduce the risk of hypertension, coronary heart disease, ulcers, chronic gastritis, goitre, pregnancy complications, cholecystitis, nephritis, slower physical development in children and complications in newborns and infants (Lutaĭ, 1992; Mudryi, 1999).

2.3.3 Adverse effects

High levels of TDS in water are generally not harmful to humans. However, while TDS is made up of numerous essential minerals that are beneficial to human health, many other potentially harmful ions may also be present. Many of the salts that make up TDS and that may cause adverse health effects (for example, arsenic, boron, cadmium, chromium, fluoride and nitrate) have maximum acceptable concentrations (MACs) established by Health Canada (refer to the most recent version of the Guidelines for Canadian Drinking Water Quality Summary Table) (Health Canada, 2022d).

High levels (> 1 000 mg/L) of TDS may cause some individuals to experience a laxative or constipation effect, and increase the risk of renal stones, arthritis problems, and eye and skin irritation (Kahlown et al., 2006; Hussain et al., 2014; Meride and Ayenew, 2016; Kozisek, 2020). Studies in Russia suggest that regular and long-term intake of extremely mineral-rich water (TDS > 1 000–2 000 mg/L) increases the risk of developing excretory system diseases (such as kidneys and urinary tract), gastrointestinal tract diseases, diseases affecting female reproductive functions, developmental problems in children, arthritis and calculi (Shtannikov and Obyedkova, 1984; Shtannikov et al., 1986; Lagutina et al., 1990; Muzalevskaya et al., 1993; Rylova, 2005). In Sri Lanka, serum creatinine levels (a clinical sign and symptom of chronic kidney disease of unknown etiology) were significantly and positively correlated with TDS content in the drinking water (range: 136.3–3 750 mg/L; mean: 687 mg/L) (Gobalarajah et al., 2020).

2.3.4 Genotoxicity and carcinogenicity

No evidence of TDS-related genotoxicity or carcinogenicity is available. IARC and the U.S. EPA have not reviewed the carcinogenicity of TDS. However, the dissolved trace heavy metals that may be present in TDS such as arsenic, beryllium, cadmium and chromium(VI) are classified as carcinogens in humans by IARC (IARC, 2018; Rahman et al., 2021). Nitrate, which may also be present in TDS, is classified as “probably carcinogenic to humans” (Group 2A) (IARC, 2018). IARC has also reviewed the potential carcinogenicity of numerous sodium-, potassium- and sulphate-containing molecules (IARC, 2018).

2.4 Hydrogen sulphide

2.4.1 Biological role

Hydrogen sulphide is not an essential element and is endogenously biosynthesized mainly by cystathionine β-lyase and the tandem enzymes cysteine aminotransferase and 3-mercaptopyruvate sulphurtransferase (Kashfi and Olson, 2013). A portion of endogenous hydrogen sulphide is also derived via non-enzymatic chemical reduction of reactive sulphur species (such as persulphides, thiosulphate and polysulphides) in the presence of reducing equivalents such as nicotinamide adenine dinucleotide phosphate (NADPH) and nicotinamide adenine dinucleotide (NADH) (Cao et al., 2019).

2.4.2 Adverse effects

No epidemiological data are available on the oral toxicity of hydrogen sulphide (WHO, 2003; ATSDR, 2016). However, alkali sulphides irritate mucous membranes and can cause nausea, vomiting and epigastric pain following ingestion (WHO, 2003). The oral dose of sodium sulphide that is fatal to humans has been estimated at 10–14 g (WHO, 1981).

When inhaled, hydrogen sulphide is acutely toxic to humans (Gosselin, 1984). Irritation of the eyes and respiratory tract can be observed at 15–30 mg/m3, and concentrations of 700–1 400 mg/m3 can cause unconsciousness and respiratory paralysis resulting in death (WHO, 1987). Hydrogen sulphide exposure levels that result in semi-consciousness or temporary unconsciousness (such as 15–30 minutes) can cause persistent neurophysical, neurobehavioural, neurocognitive, respiratory and ophthalmologic deficits (Hagley and South, 1983; Tvedt et al., 1991a; Kilburn, 1993; Snyder et al., 1995; U.S. EPA 2003b). Prolonged unconsciousness can lead to respiratory failure, hypoxia and death (Milby, 1962; Wasch et al., 1989; Khan et al., 1990; Tvedt et al., 1991b; U.S. EPA, 2003b). Overexposure to hydrogen sulphide may lead to a variety of central nervous system transitory symptoms such as dizziness, nausea, headache and more long-acting effects such as abrupt physical collapse or “knockdown,” all of which have been attributed to direct effects of hydrogen sulphide on the brain (Milby and Baselt, 1999a). Levels associated with “knockdown” and pulmonary edema have been estimated to be in the range of 500 to 1 000 ppm (695 to 1 390 mg/m3) and 250 to 500 ppm (348 to 695 mg/m3), respectively (Milby and Baselt, 1999a, 1999b; Reiffenstein et al., 1992).

2.4.3 Genotoxicity and carcinogenicity

Attene-Ramos et al. (2010) measured the genotoxicity of hydrogen sulphide using the comet assay in human intestinal epithelial cells (FHs 74 Int). Hydrogen sulphide was genotoxic in concentrations from 250 µM to 2 000 µM. Changes in gene expression were analyzed after exposure to a single genotoxic, but not cytotoxic, concentration of hydrogen sulphide (500 µM). Significant changes in gene expression were predominately observed after the four-hour exposure period as compared to the 30-minute exposure. Cultured human lung fibroblasts were treated with the hydrogen sulphide donor, sodium hydrosulphide (10–75 µM; 12–48 hours). Sodium hydrosulphide caused a concentration-dependent increase in micronuclei formation (indicating DNA damage) and cell cycle arrest (G1 phase) (Baskar et al., 2007).

Based on limited data, hydrogen sulphide has not been shown to cause cancer in humans (ATSDR, 2016). The U.S. EPA has determined that data for hydrogen sulphide are inadequate for carcinogenic assessment (U.S. EPA, 2003b). IARC has not reviewed the carcinogenicity of hydrogen sulphide.

3.0 Derivation of the health-based value (HBV)

3.1 Magnesium, calcium and hardness

3.1.1 Magnesium

The toxicological data on magnesium are insufficient to serve as the basis for developing an HBV due to lack of available data on excess magnesium level toxicity. The Institute of Medicine (IOM) derived a UL for magnesium of 2 500 mg/day for children older than 8 years, adolescents and adults (IOM, 1997). An HBV cannot be derived using the reported UL by IOM (1997) because the UL does not apply to magnesium naturally found in drinking water or in food. Magnesium, when ingested as a naturally occurring substance in drinking water or foods, has not been demonstrated to exert any adverse effects (IOM, 1997). However, adverse effects of excess magnesium intake have been observed with intakes from non-food sources such as various magnesium salts used for pharmacologic purposes, including osmotic laxatives. Ingestion of adequate levels of magnesium has a protective effect on human health while deficiencies can result in toxicologically adverse effects. Thus, no HBV is proposed for magnesium.

3.1.2 Calcium

IOM (2011) derived ULs for calcium based on calcium excretion for younger age groups and kidney stone formation for older age groups. The established UL of 2 000 mg/day for adults older than 50 years old was selected as the most appropriate UL to derive an HBV for calcium, as it is the lowest UL for individuals 1+ years old. An HBV for calcium can be calculated as follows:

Text description

The health-based value is equal to 2,000 milligrams per day multiplied by 0.2, all divided by 1.53 litres per day. This is roughly equal to 300 milligrams per litre.

Where:

- 2 000 mg/day is the UL established for adults older than 50 years old and is the most conservative UL for individuals 1+ years old (IOM, 2011); there are no data indicating that infants are more sensitive to excess calcium compared to adults.

- 0.20 is the allocation factor for drinking water; it is used as a “floor value,” since drinking water is not a major source of exposure to calcium, and there is evidence of the widespread presence of calcium in one of the other media (such as food) (Krishnan and Carrier, 2013).

- 1.53 L/day is the daily volume of water consumed by an adult (Health Canada, 2021).

3.1.3 Hardness

Hardness is most often measured as the sum of magnesium and calcium present, expressed as equivalent CaCO3, which is the traditional unit of measurement for hardness (see section 1.1.1 Calcium, magnesium, hardness). Thus, an HBV for water hardness can be derived if both magnesium and calcium have proposed HBVs. However, it is not possible to calculate a relevant HBV for magnesium since the UL for magnesium only applies to magnesium from non-food sources such as supplements (see section 3.1.1 Magnesium). Detrimental health effects caused by excess magnesium and/or calcium (that is, the two principal ions that make up water hardness) are generally caused by consumption of supplements rather than food and drinking water. Thus, an HBV for hardness is not warranted.

3.2 Chloride and sulphate

3.2.1 Chloride

To protect against the risk of elevated blood pressure associated with sodium chloride intake, IOM (2005) derived ULs for both sodium and chloride. A UL of 3 600 mg/day for individuals 13+ years old was established for chloride. An HBV can be derived using the reported UL by the IOM (2005) as follows:

Text description

The health-based value is equal to 3,600 milligrams per day multiplied by 0.2, all divided by 1.53 litres per day. This is roughly equal to 470 milligrams per litre.

Where:

- 3 600 mg/day is the UL for chloride for individuals 13+ years old (IOM, 2005).

- 0.20 is the allocation factor for drinking water; it is used as a “floor value,” since drinking water is not a major source of exposure to calcium, and there is evidence of the widespread presence of calcium in one of the other media (such as food) (Krishnan and Carrier, 2013).

- 1.53 L/day is the daily volume of water consumed by an adult (Health Canada, 2021).

3.2.2 Sulphate

Epidemiological data are insufficient to use as the basis for developing an HBV for sulphate. Although several studies have examined the effects of exposure of humans to sulphate in drinking water, none can be used to derive a dose-response characterization. Peterson (1951), Moore (1952) and Cass (1953) published long-term toxicological data showing a correlation between sulphate consumption and laxative effects. These data are insufficient because they were based on recall with little scientific weight (based on a YES/NO survey) and there were varying levels of magnesium and TDS in the water samples (U.S. EPA, 2003a). The majority of short-term toxicological studies did not find a significant association between sulphate consumption and diarrhea (Esteban et al., 1997; Heizer et al., 1997; U.S. EPA, 1999b). One short-term toxicological study published by Chien et al. (1968) showed a correlation between sulphate consumption and diarrhea in infants. However, the TDS concentration of the drinking water was high (2424 mg/L to 3123 mg/L) and there were limited participants (N = 3).

Adverse effects correlated with ingestion of sulphate were noted in two animal studies. However, neither of these studies is suitable for deriving an HBV. Narotsky et al. (2012) noted dose-related frequency of diarrhea in rats consuming sodium sulphate in drinking water. It was not stated if the frequency of diarrhea was statistically significant between dosage groups, thus the requirements for benchmark dose modelling are not met. In addition, neither a No Observed Adverse Effect Level (NOAEL) or Lowest Observed Adverse Effect Level (LOAEL) can be calculated, since sodium sulphate dosages were given in g/L in drinking water, and body weight and water consumption changed throughout the experiment. Therefore, accurate dosages could not be obtained when converting the provided g/L sodium sulphate dosages to mg/kg bw per day for the HBV calculation. Gomez et al. (1995) noted diarrhea in piglets with ingestion of dietary sulphate ≥ 1,600 mg/L. This study is also not ideal to derive an HBV for reasons similar to Narotsky et al. (2012). IOM has considered this study and concluded it was not suitable to derive a UL (IOM, 2005).

An HBV for sulphate is therefore not proposed. However, multiple international agencies have stated that catharsis/laxative effects and gastrointestinal irritation can occur when drinking water with sulphate levels ≥ 500 mg/L is ingested (NHMRC, NRMMC, 2011; WHO, 2017).

3.3 Total dissolved solids (TDS)

Since TDS is made up of numerous salts, it is challenging to derive an HBV for this parameter. The health effects correlated with specific salts that make up TDS must be analyzed separately. Many salts that make up TDS that may cause adverse health effects (for example, boron, fluoride, nitrate, arsenic and chromium) already have separate established HBVs. Thus, an HBV for TDS is not warranted.

3.4 Hydrogen sulphide

The toxicological data on hydrogen sulphide are insufficient to use as the basis for developing an HBV because all the available studies, except one, are based on inhalation/air exposure of hydrogen sulphide and not oral exposure (Beauchamp et al., 1984; Arnold et al., 1985; Jäppinen and Tola, 1990; Haahtela et al., 1992; Kilburn and Warshaw, 1995; Richardson, 1995; Vanhoorne et al., 1995; Bates et al., 1997, 1998; Hessel et al., 1997; Legator et al., 2001; WHO, 2003; Lewis and Copley, 2015; ATSDR, 2016). Only one oral animal study was found in the literature (Wetterau et al., 1964). There was a 23% decrease in body weight gain at 6.7 mg/kg bw per day in pigs exposed for 104 days and diarrheic digestive disturbances in pigs exposed to 15 mg/kg bw per day for a few days. Interpretation of this study is limited because very few details are reported (for example, no information on methods used, strain used, number of animals studies or statistics) (ATSDR, 2016). Thus, an HBV cannot be derived using animal data. IOM and Health Canada have not derived Recommended Daily Intakes for sulphide. Thus, an HBV cannot be derived using a Recommended Daily Intake such as the UL. An HBV is therefore not proposed for sulphide.

4.0 Analytical considerations

Standardized methods, commercial online analyzers and portable test kits (Table 7) are available for the analysis of calcium, magnesium, hardness, chloride, sulphate, TDS and hydrogen sulphide in source and drinking water. Method detection limits (MDL) are dependent on the sample matrix, instrumentation and selected operating conditions, and will vary between individual laboratories. These methods are subject to a variety of interferences which are outlined in the respective references or instructions.

To accurately measure the concentration of operational parameters using online analyzers and test kits, utilities should develop a quality assurance and quality control program such as those outlined in Standard Methods 3020 (APHA et al., 2018). Periodic verification of results using an accredited laboratory is recommended. Water utilities should check with the responsible drinking water authority to determine whether results from analyzers are acceptable for compliance reporting.

Drinking water utilities should discuss sampling requirements with the accredited laboratory conducting the analysis to ensure that quality control procedures are met and that method reporting limits are low enough to ensure accurate monitoring.

| Parameter | Standardized Method | Online Method | Test KitFootnote * |

|---|---|---|---|

| Calcium | X | X | X |

| Magnesium | X | X | X |

| Hardness | X | X | X |

| Sulphate | X | X | X |

| Chloride | X | X | X |

| TDS | X | X | X |

| Hydrogen sulphide | X | X | X |

|

|||

4.1 Standardized methods

4.1.1 Calcium, magnesium, hardness

Standard methods using atomic absorption spectroscopy and titration can be used for measuring the concentration of calcium and magnesium (Tables 8 and 9). SM 2340B (APHA et al., 2018) is the preferred method for calculating total hardness as the sum of the results from the individual analysis of calcium and magnesium.

| Method (Reference) |

Calcium | Magnesium | Interferences/Comments |

|---|---|---|---|

| EPA 200.5 Rev. 4.2 (U.S. EPA, 2003c) |

X | X | Analytical range not provided. |

| EPA 200.7 Rev. 4.4 (U.S. EPA, 1994) |

X | X | Analytical range not provided. Subject to matrix interference: TDS > 0.2% (w/v). |

| EPA NERL 215.1 (U.S. EPA, 1978a) |

X | N/A | Optimal range 0.2 mg/L to 7.0 mg/L using a wavelength of 422.7 nm. Subject to interference from ionic compounds.pH > 7 will result in lower calcium concentration |

| EPA NERL 242.1 (U.S. EPA, 1978b) |

N/A | X | Optimal range: 0.02 mg/L to 0.5 mg/L using a wavelength of 285.2 nm. Subject to interference from aluminum. Interference from sodium, potassium and calcium at concentration > 400 mg/L. |

| SM 3120B (APHA et al., 2018) |

X | X | Ca upper limit range: 100 mg/L using a wavelength of 317.93 nm. Mg upper limit range: 100 mg/L using a wavelength of 279.08 nm. Subject to interference when TDS > 1 500 mg/L |

| SM 3111B (APHA et al., 2018) |

X | X | Ca optimal range: 0.2 mg/L to 20 mg/L using a wavelength of 422.7 nm. Mg optimal range: 0.2 mg/L to 2.0 mg/L using a wavelength of 285.2 nm. High concentration of phosphate may interfere with the determination of calcium and magnesium; use SM 311D for calcium.. |

| SM 3111D (APHA et al., 2018) |

X | N/A | Ca optimal range: 0.2 mg/L to 20 mg/L using a wavelength of 422.7 nm. Mg optimal range:0.2 mg/L to 2.0 mg/L using a wavelength of 285.2 nm. Subject to interference from phosphate in the determination of magnesium. |

| USGS-NWQL: I-7152 (USGS, 1985a) |

X | N/A | Two analytical ranges: 0.01 mg/L to 5.0 mg/L and 1.0 mg/L to 60 mg/L. Subject to interference from phosphate, sulphate and aluminum. pH above 7 will result in lower calcium concentration. |

| USGS-NWQL: I-4447 (USGS, 1985b) |

N/A | X | Two analytical ranges: 0.01 mg/L to 5.0 mg/L and 2.5 mg/L to 50 mg/L. Subject to interference from aluminum > 2 000 g/L and sodium, potassium and calcium at concentration > 400 mg/L. pH above 7 will result in lower calcium concentration |

|

|||

| Method (Reference) |

Calcium | Hardness | Interferences/Comments |

|---|---|---|---|

| EPA NERL 130.2 (U.S. EPA, 1971a) |

N/A | X | Analytical range not provided. Metal ions may cause fading or indistinct end points. |

| EPA NERL 215.2 (U.S. EPA, 1978c) |

X | N/A | Applicable range: 0.5 mg/L to 25 mg/L as CaCO3. Strontium, magnesium and barium interferences. Alkalinity in excess of 30 mg/L may cause an indistinct end point. |

| SM 3500-Ca B (APHA et al., 2018) |

X | N/A | Analytical range not provided. Subtraction for Mg. Not recommended for sample containing phosphorus > 50 mg/L |

| SM 2340 Hardness C (APHA et al., 2018) |

N/A | X | Analytical range not provided. Some metal ions may cause interference. Determine calcium and magnesium by a non-EDTA method when there is a high level of heavy metals presents. |

| USGS-NWQL: I-3338 (USGS, 1985c) |

N/A | X | Analytical range not provided. Not applicable for acidic water with excessive amount of heavy metals. |

|

|||

4.1.2 Chloride and sulphate

The standardized method for measuring chloride and sulphate uses ion chromatography (Table 10). Turbidimetric, gravimetric and potentiometric standard methods are also available (Tables 11 and 13). SM 4500-Cl- and SM 4500-SO42- can be used to aid in the selection of method for the determination of chloride and sulphate respectively.

| Method (Reference) |

Chloride | Sulphate | Interferences/Comments |

|---|---|---|---|

| U.S. EPA 300.1, Rev. 1.0 (U.S. EPA, 1999c) |

X | X | Analytical range not provided. Low-molecular-weight organic acids, bromate and chlorite may interfere with the determination of chloride and must be purged with an inert gas. |

| SM 4110 B (APHA et al., 2017) |