Methods for Verification and Certification (MVC)

Download the alternative format

(PDF format, 1746 KB, 135 pages)

Definitions

Accreditation (Accréditation): A third-party attestation related to a verification body or certification body conveying formal demonstration of its competence and infrastructure (e.g., systems, processes) to carry out specific verification or certification tasks.

Affiliate (Parties affiliées): Two parties are affiliates if either party has the power to control the other, or a third-party controls or has the power to control the both. Affiliation also exists:

- in interlocking directorates or ownership,

- in identity of interests among members of a family and,

- where employees, equipment, and/or facilities, are shared.

Approved certification scheme (Régime de certification approuvé): Set of rules and procedures pertaining to a certification scheme that describes the objects of conformity assessment, identifies the specified requirements for the object of conformity assessment and provides the methodology for performing conformity assessment, approved by Environment and Climate Chance Canada for the purpose of certifying eligible feedstock in accordance with the applicable Land Use and Biodiversity criteria of the Clean Fuel Regulations.

Assurance system (Système d'assurance): A system of accreditation, certification, auditing-processes and procedures maintained by a certification scheme approved under the Clean Fuel Regulations.

Auditor (Auditeur): Person who conducts an audit (ISO 19011:2011).

Audits (Audit): Systematic, independent and documented processes for obtaining objective evidence and evaluating it objectively to determine the extent to which the audit criteria are fulfilled (ISO 19011:2011).

Carbon intensity (Intensité en carbone): carbon intensity, in relation to a fuel, energy source, or material input that is renewable natural gas, biogas, renewable propane or hydrogen, means the quantity in grams of CO2e per megajoule of energy contained in that fuel, energy source or material input that is released over the life cycle of that fuel, energy source or material input, including during the activities carried out during the stages of the life cycle, such as

- the extraction or production of the feedstock used to produce the fuel, energy source or material input;

- the processing, refining or upgrading of the feedstock to produce the fuel, energy source or material input;

- the transportation or distribution of the feedstock, of intermediary products or of the fuel, energy source or material input; and

- the combustion of the fuel.

Carbon-Intensity Contributor (Contributeur à l'intensité en carbone): person who applies for the approval of a carbon intensity under sub-section 80(1) of the Clean Fuel Regulations, for a set of activities carried out over the life cycle of a fuel in the liquid class or a low-carbon-intensity fuel with the intention to transfer the approved carbon intensity to a registered creator or foreign supplier or to another carbon-intensity contributor.

Certification bodies (Organisme de certification): Third-party conformity assessment bodies (ISO 17065:2012) making certification decisions and issuing certificates.

Certification scheme owner (Propriétaire du régime de certification): Legal entity that develops and maintains a certification scheme.

Certification program related to the Land Use and Biodiviersity criteria of the Clean Fuel Regulations (Programme de certification relatif à l'utilisation des terres et de la biodiversité du Règlement sur les combustibles propres): Set of rules and procedures pertaining to an approved certification scheme put in place for the purpose of certifying eligible feedstock in accordance with the applicable Land Use and Biodiversity criteria of the Clean Fuel Regulations.

Clean Fuel Regulations - Land Use and Biodiversity conformity assessment system (Système d'évaluation de la conformité à l'égard de l'utilisation des terres et de la biodiversité dans le cadre du Règlement sur les combustibles propres): Set of common rules and procedures required by the Clean Fuel Regulations for the approval and management of certification schemes for the purpose of certifying feedstock sourced from agriculture and forest biomass against the applicable Land Use and Biodiversity criteria of the Clean Fuel Regulations.

Client (Client): Organization or person requesting verification or certification.

Controls (Contrôles): Responsible party's policies and procedures that help to ensure that the statement is free from material misstatement and conforms to the criteria.

Criteria (Critères): Policy, procedure, or requirement used as a reference against which the statement is compared.

Data trail (Trace des données): A complete record by which information can be traced to its source.

Designated accreditation body by Environment Climate Change Canada (Organisme ou organisation d'accréditation désigné par Environment et Changement climatique Canada): Authoritative body that:

- performs accreditation;

- is a member of the International Accreditation Forum and meets the requirements set out in ISO/IEC Standard 17011 for the purpose of the verification requirements of the Clean Fuel Regulations; or

- Is a member of the International Accreditation Forum or an equivalent body, and meets the requirements set out in ISO/IEC Standard 17011 for the purpose of the certification requirements of the Clean Fuel Regulations.

The accreditation organization reviews the procedures, processes, and qualifications of the verification or certification body, and declares whether the body is competent, its infrastructure (e.g., systems, processes) is compliant with the requirements and the body is conducting verification or certification activities in accordance with requirements. The accreditation organization also monitors accredited bodies to ensure that they maintain competent personnel and operate with transparency and impartiality.

Emissions (Émissions): A release of greenhouse gases to the atmosphere but in this document it is also used as an abbreviation for emissions, removals, and storage for brevity.

Feedstock harvester (Producteur de matières premières): A person who cultivates and/or harvests feedstock used to produce low carbon-intensity fuel.

Greenhouse gas (Gaz à effet de serre): Gaseous constituent of the atmosphere, both natural and anthropogenic, that absorbs and emits radiation at specific wavelengths within the spectrum of infrared radiation emitted by the Earth's surface, the atmosphere, and clouds.

Independent reviewer (Examinateur indépendant): Competent person, not a member of the verification team, who reviews the verification as required under the Clean Fuel Regulations. The independent reviewer cannot be a sub-contractor to the verification body.

Impartial verification or certification (Vérification ou certification impartiale): The verification or certification process is performed by an objective (impartial) third-party.

Intended user (Utilisateur prévu): is Environment and Climate Change Canada, who relies on the reported information to administer the Clean Fuel Regulations.

Level of assurance (Niveau d'assurance): A degree of confidenceFootnote 2 in a statement. There are two levels: limited and reasonable. The Clean Fuel Regulations requires a reasonable level of assurance for verifications.

Local language (Langue locale): The language spoken in the country or location where the responsible party is located (facility/operations) and where the verification or certification activities take place.

Material changes (Modifications d'importance significative): Changes that are capable of modifying the decisions of the intended users, including changes of boundaries or scope in reporting under the Clean Fuel Regulations requirements.

Material facility expansion (Agrandissement d'importance significative de l'installation): Changes in production or emissions from the prior year of 10% or more that are due to changes at the site, and not changes in the feedstock or input quantity or quality.

Material emission (Émission d'importance significative): An emission misstatement that could change the final reported number to a degree that would affect the intended user's decisions.

Material site (Site d'importance significative): Is where any misstatement at the site could change the final reported number at a material level (quantitative materiality thresholds apply).

Materiality (Importance relative): Concept that individual misstatements or the aggregation of misstatements could influence the intended users' decisions.

Minister (Ministre): Minister of the Environment

Misstatement (Déclaration erronée): A difference between the amount reported, classification, presentation, or disclosure of an item and the amount reported, classification, presentation, or disclosure that is required for the item to be in accordance with the criteria. Misstatements arise from errors or fraud. Misstatements can also be classified as errors, omissions, and misreportings, where misreportings include differences in classification, presentation and disclosure.

Organization (Organisme): Person or group of people that has its own functions with responsibilities, authorities, and relationships to achieve its objectives.

Overall quantitative materiality (Importance relative globale): Concept that individual misstatements or the aggregation of misstatements could influence the intended user's decisions at the reporting level of the report or application.

Performance materiality (Importance relative liée au rendement): A value set lower than what might be quantitatively material to the intended user to identify misstatements that, when aggregated, might be material.

Prime verification body (Organisme de vérification principal): When using outsourcing, the verification body that is responsible for the overall design and reporting of the verification.

Responsible party (Partie responsible): Person or persons responsible for the provision of the applications or reports made under the Clean Fuel Regulations. These responsible parties are: a fossil fuel primary supplier, foreign supplier, carbon-intensity contributor or a credit creator.

Stakeholder (Intervenant): Individual or group that has an interest in any decision or activity of an organization (adapted from ISO 26000).

Third-party (Tierce partie): An impartial entity that is not one of the primary parties (e.g., the responsible party or the intended user) in the transaction.

Uncertainty (Incertitude): A parameter associated with quantification, which characterizes the dispersion of the values that could be reasonably attributed to the quantified amount.

Verification (Vérification): Process for evaluating a statement of historical data and information to determine if the statement is materially correct and conforms to criteria.

Verification body (Organisme de verification): An accredited, impartial organization with responsibility for performing and reporting on the verification process.

Verifier (Vérificateur): Competent and impartial person, member of an accredited verification body, with responsibility for performing and reporting on the verification process.

Acronyms

| Acronym or abbreviation | Meaning |

|---|---|

| ANAB | ANSI National Accreditation Board |

| ANSI | American National Standards Institute |

| CAATT | Computer Assisted Audit Tools and Techniques |

| CCS | Carbon Capture and Storage |

| CFR | Clean Fuel Regulations |

| CFR-LUB | Clean Fuel Regulations – Land Use and Biodiversity criteria |

| CFR-LUB CAS | Clean Fuel Regulations – Land Use and Biodiversity Conformity Assessment System |

| CI | Carbon Intensity |

| CO2e | Carbon dioxide equivalents |

| CS | Certification Scheme |

| ECCC | Environment and Climate Change Canada |

| EOR | Enhanced Oil Recovery |

| EV | Electric Vehicles |

| GHG | Greenhouse Gases |

| GWP | Global Warming Potential |

| HHV | Higher Heating Value |

| IAF | International Accreditation Forum |

| ISO | International Organization for Standardization |

| LCA | Life Cycle Assessment |

| LHV | Lower Heating Value |

| SCC | Standards Council of Canada |

Introduction

Purpose and structure

This document has been written for verification bodies and their verifiers as well as certification bodies and their auditors working with the Clean Fuel Regulations (CFR); and lays out the regulatory requirements and guidance in their implementation.

PART 1 and PART 2 of this document outline requirements and guidance for verification bodies and their processes. The framework and requirements concerning the Clean Fuel Regulations – Land Use and Biodiversity Conformity Assessment System are outlined in PART 3 of this document. This part lays out requirements for the approval of certification schemes that can be used for the purposes of the Land Use and Biodiversity Criteria of the CFR, as well as the relevant requirements for certification bodies conducting certification activities under a CFR-approved certification scheme.

Schedule for verification

Under the CFR, reporting entities are required to submit each regulatory application or report with the corresponding verification report as listed in Table 1. The content of a verification report is outlined in Appendix A. The reporting requirements are established in accordance to the specified schedule set out in the Regulations. Appendix B summarizes the reporting timelines for the submission of the verification reports per type of application or report in a standard year. Appendix C presents the reporting timelines for the first submission of the verification report per type of application or report based on the coming into force of each component of the CFR.

| Report | Verification report submission deadline |

|---|---|

| Application for approval of carbon-intensity for low-carbon-intensity fuels, compressed and liquefied gases, hydrogen, or electricity (sub-section 80(1)) | On the day the application is submitted (section 130) A verification report will be submitted with Fuel LCA Model CI Applications beginning June 30th, 2024. |

| Application for a temporary approval of carbon-intensity for low carbon-intensity fuels, compressed and liquefied gases, hydrogen, or electricity (sub-section 91(1)) | On the day the application is submitted (section 130) A verification report will be submitted with Fuel LCA Model CI Applications beginning June 30th, 2024. |

| Annual credit creation report for the supply of fuel(s) or energy sources to vehicles (section 120) | On the day the report is submitted (sub-section 131(3)), no later than April 30th following the compliance period. Exceptions: the report is not required to be verified if no compliance credits were created during the compliance period to which the report relates (paragraph 131(2)(a)). For the Annual credit creation report due 2023 for the early credit creation period, the report with verification is due on June 30th, 2023 (if credits were created). |

| Annual credit creation reports for CO2e emission reduction projects (section 120) | On the day the report is submitted (sub-section 131(3)), no later than April 30th following the compliance period. Exceptions: the report is not required to be verified if no compliance credits were created during the compliance period to which the report relates (paragraph 131(2)(a)). For the Annual credit creation report due 2023 for the early credit creation period, the report with verification is due on June 30th, 2023 (if credits were created). |

| Quarterly credit creation report for the production or import of eligible low-carbon-intensity fuel(s) or for the supply of fuel(s) or energy sources to vehicles that relates to a low-carbon-intensity fuel (section 121) | Quarterly credit creation reports are not subject to verification with the exception of the one-time combined quarterly credit creation reports (category 2 & category 3 for low CI fuel) for the compliance period that ends on December 31, 2022 and must be submitted no later than June 30th, 2023 (sub-section 121(3)). Exception: the report is not required to be verified if no compliance credits were created during the compliance period to which the report relates (paragraph 131(2)(a)). |

| Credit adjustment report for the production or import of eligible low-carbon-intensity fuel(s) or for the supply of fuel(s) or energy sources to vehicles that relates to a low-carbon-intensity fuel (section 122) | On the day the report is submitted (sub-section 131(3)), no later than June 30th following the compliance period. Exception: the report is not required to be verified if no compliance credits were created during the compliance period to which the report relates (paragraph 131(2)(a)). |

| Carbon Intensity Pathway Report (section 123) | On the day the report is submitted (sub-section 131(3)), no later than April 30th following the compliance year. |

| Material Balance Report (section 124) | On the day the report is submitted (sub-section 131(3)), no later than April 30th following the compliance year. |

| Compliance credit revenue report (section 125) | On the day the report is submitted (sub-section 131(3)), no later than July 31st following the compliance year. Exception: the report is not required to be verified if no revenue was created from the transfer of compliance credits during the compliance period to which the report relates or during the two preceding compliance periods (paragraph 131(2)(b)). |

| Compliance report (section 127) | On the day the report is submitted (sub-section 131(3)), no later than July 31st following the compliance year. |

| Complementary compliance report (section 128) | On the day the report is submitted (sub-section 131(3)), no later than December 15th following the compliance year. |

Schedule for land use and biodiversity conformity assessment system

The application process for the approval of certification schemes for the purpose of certifying feedstock used to produce low-carbon-intensity fuels will be made available prior to the coming into force of the Land Use and Biodiversity criteria of the CFR on January 1st, 2024. A certification scheme's owner will then have the possibility to fill out an application and submit all the documentation demonstrating compliance with the regulatory requirements. Environment and Climate Change Canada (ECCC) will then assess whether the certification scheme applying for approval demonstrates full compliance with the applicable regulatory requirements and provide a response to the applicant.

1 Requirements for verification bodies

1.1 Accreditation requirements

An organization is eligible to be a verification body if the organization:

- is a legal entity that has legal capacity to enter into agreements or contracts, assume obligations, incur and pay debts, sue and be sued, and to be held responsible for its actions

- is accredited by the Standard Council of Canada (SCC) or the ANSI National Accreditation Board (ANAB) (sub-section 138(1)) or is accredited by a designated accreditation body that is a member of the International Accreditation Forum and meets the requirements set out in ISO/IEC Standard 17011 (sub-section 138(2)), to the most recent version of the following standards:

- ISO/IEC 17029 Conformity assessment — General principles and requirements for validation and verification bodies, with the specific scope of ISO 14065 General principles and requirements for bodies validating and verifying environmental information (paragraph 138(1)(a))

- ISO 14066 Greenhouse gases – Competence requirements for greenhouse gas validation teams and verification teams (paragraph 138(1)(b))

- has a qualified independent reviewer (section 139)

- has a qualified team (see 1.2) in order to be accredited to the technical sector(s) in Table 2 applicable to the scope of the services that will be provided (section 140)

A verification body cannot perform verification activities if the verification body's accreditation is suspended or revoked by an accreditation organization (section 137).

| Sector | Description | |

|---|---|---|

| Sector 1 | Fossil Fuels (paragraph 140(1)(a)) | Production, import, distribution, and delivery (including at fueling stations) of fossil fuels to end users and distribution companies |

| Sector 2 | Renewable/Bio/Low-carbon-intensity (CI) Fuels (paragraph 140(1)(b)) | Production, import, distribution, and delivery (including at fueling stations) of non-fossil, low-carbon-intensity (CI), renewable, and biofuels |

| Sector 3 | Electricity (paragraph 140(1)(c)) | Production, distribution of electricity, and transactions related to electricity (including at charging stations for EVs) |

| Sector 4 | Green Hydrogen (from non-fossil fuels) (paragraph 140(1)(d)) | Production, import, distribution, and delivery of green hydrogen from renewable sources. |

To demonstrate sector competence, the team collectively demonstrates two years of work experience in that sector, which includes a basic knowledge of the general processes, GHG emissions, removal and storage across the lifecycle of the products in that sector, and may include relevant GHG verifications.

In the case of a verification of applications or reports that involve both fossil and renewable/bio/low-carbon-intensity fuels, such as could be in the co-processing of fuels, the verification body is accredited to both Sector 1 and Sector 2.

1.2 Team

1.2.1 Team composition

In accordance with ISO 14066, the verification team, excluding specialists, collectively demonstrates that they have the necessary skills and competencies to undertake a verification.

Verification teams demonstrate that they:

- Understand the requirements of the CFR, including:

- Fuels regulated (fossil), low carbon intensity fuels and creating compliance credits;

- The baselines chosen;

- The reduction requirements, if applicable;

- Scopes of the lifecycle;

- The regulatory criteria;

- Assurance level required; and

- Mandatory reporting requirements.

- Understand greenhouse gas science, including:

- The processes that emit, remove or store GHG including technical issues associated with their quantification (e.g., emission factors, emission inventories, production, etc.), monitoring, and reporting;

- The applicability and limits of the prescribed quantification methodologies;

- The types of GHG sources and sinks associated with fuel lifecycle; and

- The Specifications for Fuel LCA Model CI Calculations.

- Understand the verification process as described in ISO 14064-3:2019 including the aspects listed in Table 3.

- Understand life cycle assessments, including

- The concept of functional units;

- The fuel system boundaries;

- Any allocation procedures; and

- The assumptions, limitations, data quality and uncertainty used in the lifecycle.

- Have understanding of the applicable sector(s) to which they are accredited described in Table 2, including an understanding of:

- The GHG sources, sinks, and reservoirs, common to the fuel lifecycle;

- The operational processes and production; and

- The uncertainty in the measurements and how this affects the assertions.

- Have understanding in Computer Assisted Audit Tools and Techniques (CAATTs), for the verification of automated data management systems, when applicable, including:

- Have knowledge of the principles and rules guiding computer-assisted audits:

- An understanding of the Information Technology (IT) environment, and the core applications and relevant database structure;

- Have understanding and experience of examining highly automated data management systems using CAATTs.

- Have knowledge of the principles and rules guiding computer-assisted audits:

- Have a team member who speaks the applicable local language(s) fluently.

- Have the following formal training:

- ISO 14064-3:2019 training;

- CFRFootnote 4 verifier's basics course; and

- CFR verification recurrence course (every two years).

The experience and the training completion of each member of the verification team is documented.

Table 3: Competency Requirements Related to Verification Processes

Verification

- The process and linkages between objectives, risk identification, evidence gathering procedures design, evidence evaluation, and conclusion forming;

- Roles and responsibilities;

- Different levels of assurance and the types and extent of evidence gathering techniques used in each verification;

- Verification criteria and the assessment of acceptable criteria;

- The various forms of materiality and where they are applied in the verification process;

- Different types of evidence gathering activities and the strength and types of evidence they collect;

- The requirements for site-visits;

- Assessment of data management systems and controls, including methods to identify failures and their impact on assertions;

- Methodologies for establishing data trails for material items;

- Different types of conclusions and when they can be applied;

- Development of a conclusion based on the evidence; and

- Assessment of qualitative components, including the need for disclosure and the principle of conservativeness.

1.2.2 Team leader

For each verification assignment, the verification team must include a team leader who is an employee of the verification body (sub-section 141(1)).

The team leader has sufficient verification knowledge as described in ISO 14065 and 14066, which includesFootnote 5:

- Understanding of the verification process including the design, typical evidence gathering activities, significant decision points, materiality interpretations;

- Understanding of CAATTs for the verification of automated data management systems;

- Understanding of the requirements of the CFR;

- Understanding of the verification body procedures;

- Technical competence in the applicable sector(s) described in Table 2;

- Understanding of the documentation requirements of their role, including the documentation of misstatements and data gaps in conclusion and their resolution; and

- Sufficient knowledge to manage the verification team, including each member's competencies, in order to complete a verification assignment.

The team leader has the following formal training:

- ISO 14064-3:2019 training;

- CFRFootnote 6 verifier's basic course; and

- CFR verification recurrence course (every two years).

The team leader demonstrates experience in performing verifications, such as two years of experience in GHG verification, and participated in a minimum of five GHG verifications in the past ten years.The training completion and the experience and of the team leader is documented.

The team leader has the authority to approve verification plans and evidence gathering plans.

1.2.3 Specialists

Certain verification subjects will require a specialist on the team (sub-section 141(2)). For any specialists, the following requirements are applicable:

- Any applicable professional credentials must be current and recognized as per CFR requirements;

- Any specialist must have at least four years of relevant work experience within the last 10 years in the applicable field of specialisation or technical expertise (sub-section 141(3));

- Demonstration of the knowledge and proficiency is done by providing a curriculum vitae and references as a proof; and

- Specialists may not subcontract nor delegate their work (paragraph 142(1)(a)).

The specialist's requirements are as follows:

- For the verification of applicationsFootnote 7 or reports that relate to the use of feedstock derived from agricultural or forest biomass in accordance with the Land Use and Biodiversity (LUB) criteria of the CFR, the team must include an individual who is a specialist in agriculture, forestry or a specialist in biodiversity, as appropriateFootnote 8, (paragraph 141(2)(a)).

- The specialist must have professional credentials recognized by the relevant Canadian professional association or provincial authority (i.e., Agriculture engineer, Agrologist, Professional forester or Forest engineer) or must hold a diploma equivalent to a Canadian bachelor's degree in biology, natural sciences or environmental sciences;

- In the case of non-Canadian professionals, specialists' professional credentials or bachelor's degree in biology, natural sciences or environmental sciences must be officially recognized by the national authority of the country where the services are provided.

- For the verification of applications or reports that involve carbon sequestration in geological formations, including enhanced oil recovery, the team must include an individual that is specialist in geological carbon storage (paragraph 141(2)(b)).

- The specialist must have professional credentials recognized by the relevant Canadian professional order or provincial authority (i.e., geologist). In the case of non-Canadian professionals, their credentials must be recognized by the national authority of the country where the services are provided;

- The purpose of the specialist in geological carbon storage is to establish the suitability of a geological formation for use as a reservoir, including the potential for leakage.

- For the verification of reports that involve the generation or use of revenue, expenses, funds or tax treatments, the team must include an individual that is a specialist in financial accounting (paragraph 141(2)(d)).

- The specialist must be a recognized Canadian Chartered Professional Accountant (CPA);

- The CPA has the knowledge of, and proficiency in the accounting basis for the entity that they are auditing (e.g., International Financial Reporting Standards (IFRS), Canadian General Accepted Accounting Standards (Canadian GAAP), Accounting Standards for Private Enterprises (ASPE), or Non-GAAP reporting (for tax purposes));

- The purpose of the specialist in financial accounting is to review the generation or use of revenue, expenses, funds or tax treatments in accordance with the accounting basis of the entity.

- For the verification of applications or reports that use the Fuel LCA Model and/or the Specifications for Fuel LCA Model CI Calculations, the team must include an individual who is a qualified lifecycle assessment critical reviewer (paragraph 141(2)(c).

- The specialist must understand and be able to apply the requirements of lifecycle assessment according to the most recent version of:

- Standard ISO 14040 Environmental management — Life cycle assessment — Principles and framework;

- Standard ISO 14044 Environmental management — Life cycle assessment — Requirements and guidelines; and

- Technical Specification – ISO/ TS 14071 Environmental management — Life cycle assessment — Critical review processes and reviewer competencies: Additional requirements and guidelines to ISO 14044:2006.

- The LCA critical reviewer must have knowledge of the following:

- The Specifications for Fuel LCA Model CI Calculations and current LCA practice;

- LCA dataset generation and LCA dataset review;

- Critical reviews of LCA;

- All scientific disciplines relevant to LCA; and

- Environmental, technical and other relevant performance aspects of the product system(s) assessed.

- The LCA critical reviewer must have the following experienceFootnote 9:

- Actively participated to at least two LCAs as a LCA practitioner that addressed GHG emissions inventory or the global warming impact category and were compliant with ISO 14040/14044 standards; and

- Carried out or participated in at least one LCA critical review as an internal expert or two LCA critical reviews as an external expert within the last ten years.

- The specialist must conduct the LCA critical review in accordance with subsection 6.2 of ISO Standard 14044.

- The specialist must understand and be able to apply the requirements of lifecycle assessment according to the most recent version of:

1.3 Independent reviewers

Each verification is reviewed by a qualified independent reviewer. The independent reviewer must be an employee of the verification body and must have as a minimum the same competencies as specified in ISO 14065 for the team leader (section 139). According to ISO/IEC 17029 and ISO 14065, independent reviewers may provide feedback to the verification teams but cannot participate in planning or execution of verification activities. Independent reviewers are selected such that they are competent and different from the team. The skills and experience an independent reviewer include:

- Experience and a theoretical understanding of the verification process, as applicable, including the design, typical evidence gathering activities, significant decision points, materiality interpretations;

- An understanding of CAATTs for the verification of automated data management systems, as applicable;

- An understanding of the requirements of the CFR;

- An understanding of the requirements of an independent reviewer;

- An understanding of the verification body procedures;

- The technical competence in the applicable sector(s) described in Table 2; and

- The documentation of training completion and experience.

The independent review may be conducted concurrently with the verification process to allow significant issues identified by the independent reviewer to be resolved before the opinion is issued, provided that the impartiality of the independent reviewer is maintained, and the activities planned and undertaken by the independent reviewer(s), including the results, are documented.

1.4 Subcontracting

The verification body may subcontract certain services as part of the verification. In subcontracting services, the verification body ensures that there is, in accordance with section 142 and ISO/IEC 17029:

- an assessment as to whether the subcontractor has the necessary skills and competencies for their role identified in the verification;

- adequate documentation of the subcontractor's qualifications;

- a written contract between the verification body and the subcontractor (paragraph 142(1)(a));

- an assessment as to the impartiality of the subcontractor;

- a signed written confidentiality agreement for all personnel who have access to confidential information (paragraph 142(1)(b)); and

- a process for evaluating the conclusions and quality of the subcontractor's work.

In subcontracting, the verification body is responsible for the management, quality, and integration of the conclusions of the subcontractor into the verification report and into the opinion ((paragraph 142(1)(c)).

The verification body is responsible for ensuring that any subcontractors meet competency requirements (sub-section 141(2) and (3)) and impartiality requirements (sections 145 to 147).

The roles of team leader and independent reviewer cannot be subcontracted (sub-section 142(1)).

1.5 Outsourcing

Verification bodies may outsource to other verification bodies a portion of the verification activities under the following conditions (section 143):

- The prime verification body can only outsource a maximum of 30% of the scope of the verificationFootnote 10 (paragraph 143(1)(a)). The outsourced activities and documentation of the activities and level of effort of the outsourced body are documented according to ISO/IEC17029;

- The prime verification body must take responsibility for assurance on the final report (paragraph 143(1)(d)). This is the verification body that provides oversight for the verification;

- The entire lifecycle must be addressed by the verification report, where applicable (paragraph 143(1)(e));

- All verification bodies meet the requirements set out in CFR (i.e. accreditation, impartiality, competence) (paragraph 143(1)(c) and sub-section 143(2));

- The prime verification body informs their client of their use of outsourced verification bodies in accordance with ISO/IEC 17029;

- The prime verification body must have a documented agreement with the outsourced verification body (paragraph 143(1)(b));

- The prime verification body is responsible for the direction, supervision and performance of the outsourced verification bodies including ensuring that they are in compliance with the requirements of the CFR (i.e. accreditation, impartiality, competence) (paragraph 143(1)(c) and sub-section 143(2)):

- The prime verification body is responsible for ensuring the verification is conducted in accordance with the requirements of the CFR (e.g., ISO 14064-3; 2019, level of assurance, materiality thresholds);

- The prime verification body establishes the verification strategy, risk assessment, materiality and performance materiality for the statement as a whole:

- Verification risk is a function of the risk of material misstatement in the report or application and the risk the verifier may not detect these misstatements. The verification risks include the risk that the outsourced verification body may not detect misstatements;

- The prime verification body establishes materiality for the application or report. Materiality for the outsourced verification scope is set lower than the materiality of the application or report to reduce the probability that aggregated uncorrected and undetected misstatements will exceed the application or report materiality.

- The prime verification body determines the scope of the verification performed by the outsourced verification body, their role in the verification, the performance materiality associated with their scope, and reporting requirements;

- The prime verification body determines the type of work performed by its verification team and the outsourced verification team. The prime verification body determines the nature, timing, and extent of its involvement in the work of the outsourced verification body;

- If the scope of work of the outsourced verification body involves material line items in the final application or report, the prime verifier involves the outsourced verification body in the risk assessment to ensure that the risk is adequately addressed. Examples:

- A BC prime verification body has outsourced part of the verification to a Northwest Territory verification body because of travel costs and local experience. The scope of work contains a material line item related to biodiversity. The prime and outsourced verification bodies need to discuss the risk assessment for the material line item because the outsourced verification body will have knowledge about the local ecosystem which will aid in assessing the potential and magnitude of the risk.

- A prime verification body has outsourced the IT component of the verification to another (outsourced) verification body because of specialized software and experience. The scope of the outsourced work contains many material line items. The prime and outsourced verification bodies should discuss the risk assessment for the material line items because the outsourced verification body will have a more in-depth knowledge of the potential and magnitude of the risks. In this situation, further discussions should occur about the evidence gathering activities as the outsourced verification body may have knowledge about alternative and/or more efficient methods for gathering evidence.

- The prime verification body is responsible for evaluating the sufficiency and appropriateness of the evidence obtained, which includes evaluating the adequacy of the outsourced verification body's work:

- If the outsourced verification work is insufficient or inappropriate, additional evidence gathering activities are designed and performed by the prime verification body.

- The prime verification body evaluates the effect of any uncorrected misstatement in the outsourced verification work on the application or report as a whole;

- The prime verification body is responsible for issuing the verification statement.

Examples of outsourcing:

- A verification body based in Ontario may outsource to a verification body based in Manitoba the evidence gathering activities that occur in Manitoba.

- A verification body may outsource the computer-assisted audit evidence gathering activities to another verification body that has developed or has access to specialized software tools.

- A verification body may outsource interview evidence gathering activities to another verification body that has established relations with the interviewees.

- A verification body may outsource the verification of a carbon-intensity contributor's CI value.

1.6 Reliance on verifications performed by other verification bodies

A verification body (prime verifier) may rely on the verification statement of another independent verification body (relied-upon verifier) under the following conditions (section 144):

- The prime verification body must take responsibility for assurance over the entire verification statement (paragraph 144(b));

- The entire lifecycle must be addressed by the verification statement, where applicable (paragraphs 144(b) and (c));

- The prime verification body can only rely on another independent verification statement if it represents, at a maximum, 15%Footnote 11 of the scope of the prime verification assignment (paragraph 144(a));

- Both verification bodies meet the requirements set out in CFR (i.e. accreditation, impartiality, competence) (paragraph 144(d));

- Both verifications are conducted in accordance with the requirements set out in the CFR (e.g., ISO 14064-3; 2019, quantification criteria) (paragraph 144(d));

- The engagement type, level of assurance, scope, objectives, criteria, and materiality are appropriately aligned. The engagement type (i.e., verification), level of assurance (i.e., reasonable), and criteria (i.e., the requirements of the CFR) should be consistent between the verifications. The relied-upon verification scope connects logically with the entire verification scope with no gaps;

- The prime verification body communicates to the relied-upon verifier that their report will be relied upon;

- The prime verification body discloses the amount of reliance on the other independent verifier's report in their verification statement;

- The prime verification body includes the relied-upon verification statement and the associated application or report in their documentation.

Examples

- For the verification of the amount of a low-carbon-intensity fuel that has imported feedstock, one verification body may verify the amount of feedstock from harvest to export point and another verification body may verify the amount of feedstock from export point to final use including the production of the low-carbon intensity fuel.

- A verification body based in Brazil has provided a verification statement for the amount of sugarcane to a port of exit in Brazil. A Canadian verification body, acting as prime verifier, could provide verification on the Materials Balance Report by:

- Verifying the information from the Brazilian port of exit to delivery of a final product in Canada; and

- Relying on the Brazilian body's verification (assuming all parties meet the requirements in the CFR in relation to competence, conflict of interest, any applicable criteria).

- In the case of a carbon-intensity contributor that produces renewable natural gas for consumption, one verifier could provide verification on the CI value for the renewable natural gas, and another verifier could rely on that verification when providing a verification on the producer's fuel.

1.7 Management of impartiality

1.7.1 Impartiality requirements

In addition to the impartiality requirements in ISO 14064-3:2019 and ISO/IEC 17029 with the scope of ISO 14065, the verification team, including subcontractors, and the independent reviewer must be free from any conflict of interest (threat to impartiality). Any members of the verification team, including subcontractors or members of the outsourced verification body's team, and independent reviewers must be independent of (section 145):

- The employees of the federal public administration who administer or implement the CFR or carry out any related activitiesFootnote 12.

- The person who is making the application or submitting the reportFootnote 12.

1.7.2 Threats to impartiality

The independence or impartiality requirements of the CFR, ISO/IEC 17029 with the scope of ISO 14065, and ISO 14066 apply to any of the circumstances described under this section. Threats to impartiality may exist at the present time, may be reasonably foreseen to exist in the future, or may be perceived as such by a reasonably well-informed observer, who could make the assumption that a threat to impartiality exists, whether or not it is the case. Threats to impartiality include:

- Self-Interest

- Self-Review

- Advocacy

- Familiarity

- Intimidation or Economic Implications

A self-interest threat occurs when the verification body or a member of the verification team can directly benefit, financially or otherwise, based on the conclusion of the verification. For example:

- Owning shares of the company being verified;

- Having a close business relationship with the client;

- Contingent fees relating to the results of the verification;

- Seeking potential employment with the client;

- Acting as a broker-dealer (registered or unregistered), promoter, or underwriter on behalf of the client;

- Using, managing, or deploying the reinvestment revenue for expanding electric vehicle charging infrastructure and/or reducing the cost of electric vehicle ownership;

- Taking an equity position in a project listed in the CFR system; or

- Taking equity or payment in the form of future revenues from a project.

A self-review threat occurs when the verification body or a member of the verification team could be in a position of reviewing their own work.

For example:

- Developed the modelling software used in the report or application being verified;

- Providing consulting services that directly impinge on the report or application being verified, such as designing or implementing the data management systems;

- Compiling or reporting the information for the application or report being verified; or

- Verifying a report that relates to the same carbon intensity addressed in an application or report that they previously verified.

1.7.2.1 Specific self-review limitations

The CFR does not permit individual verifiers, including subcontractors and outsourced verifiers, or independent reviewers to verify a subject matter for which there is a self-review risk. Any member of the verification team and the independent reviewer cannot perform the verification or independent review of the carbon intensity pathway report, the credit creation report or the credit adjustment report if they previously participated in the verification or independent review of the application for approval or temporary approval of the same carbon intensity for the same client unless five years have lapsed between the end of the prior engagement and beginning of the verification (sub-section 147(5)). Additionally, any member of the verification team and the independent reviewer cannot perform the verification or independent review of the credit creation report or the credit adjustment report if they previously participated in the verification or independent review of the carbon intensity pathway report during the same compliance period about the same carbon intensity for the same client (sub-section 147(6)).

Examples of specific self-review circumstances under the CFR that are not permitted include:

- A LCA critical reviewer for the verification of the application for approval of carbon intensity becomes the LCA critical reviewer for the corresponding verification of the carbon intensity pathway report;

- Verifying the creation of a CI value (e.g. the application for approval of carbon intensity) while verifying a report that uses that CI value (e.g., carbon intensity pathway report, credit creation reports);

- A verifier for the application for approval of carbon intensity is the verifier for the carbon intensity pathway report or credit creation report that uses the approved CI value;

- The team leader involved in the verification of the application for a temporary approval of a carbon intensity of a low-carbon fuels is a team member for the credit creation report for that same low-carbon fuel;

- Verifying when they were involved in the certification of the same subject matter. (e.g., feedstock or IT system that is used to generate compliance credits).

An advocacy threat occurs when the verification body or a member of the verification team may be perceived to promote a responsible party's position or opinion to the point that objectivity may, or may be perceived to be, compromised. For example:

- Dealing in, being a promoter, or providing matchmaking services for compliance credits in the CFR system;

- Participating in the development of quantification methodologies for the CFR system;

- Advocating on behalf of the responsible party to advance a position or point of view on an issue that directly affects the report or application being verified; or

- Acting as an advocate on behalf of the responsible party in litigation or in resolving disputes with other third parties.

A familiarity threat occurs when the verification body or a member of the verification team, by virtue of a close relationship with a responsible party, its directors, officers, or employees, becomes overly sympathetic to the responsible party's interests.

For example:

- A person on the verification team has a close personal relationship with a person who is in a critical compilation role at the responsible party;

- Acceptance of significantFootnote 13 gifts or hospitality from the responsible party;

- A member of the verification team has verified the same subject matter for a prolonged period of time and has developed relationships with the verified entity as a consequence of that exposure.

1.7.2.2 Specific familiarity threat limitations

The CFR does not permit individual verifiers, including subcontractors and outsourced verifiers, or independent reviewers to verify a subject matter for which there is a familiarity risk. Any member of a verification team and the independent reviewer may participate in the verification of the same application or report for a maximum of five consecutive years for the same reporting entity (sub-section 147(1)). The five-year period begins on the execution date for verification services (usually the contract dateFootnote 14) under these Regulations and ends on the date the final verification opinion is submitted to the MinisterFootnote 15. The five-year limit does not reset upon a change in ownership or operational control of the responsible party required to submit its applications or reports under the CFR to be verified.

After reaching the five-year limit, a three-year lapse must occur before a member of the verification team or the independent reviewer may resume verification activities for the same subject matter and for the same reporting entity (sub-section 147(2)).

Any member of a verification team and the independent reviewer is not permitted to perform a verification or independent review for the same reporting entity of which they were an employee, unless five years have lapsed between the end of their employment and the beginning of the verification engagement (sub-section 147(3)). Additionally, any member of the verification team and the independent reviewer should not perform verification activities in they were involved in any enterprise related to the scope of the verification to be performed within the last five years. Examples include:

- the low-carbon-intensity fuel provider;

- a fuel supplier that purchases or acquires low-carbon-intensity fuel from the low-carbon fuel provider;

- a person who sells or transfers low-carbon-intensity fuel to the low-carbon-intensity fuel provider;

- a person who manufactures low-carbon-intensity fuel that is sold to the low-carbon-intensity fuel provider; or

- an affiliate of the low-carbon-intensity fuel provider or of a fuel supplier.

Any member of a verification team and the independent reviewer is not permitted to perform a verification or independent review required under the CFR if they were an employee of the federal public administration who administers or implements these Regulations or carries out any related activity, unless five years have lapsed between the end of their employment and the beginning of the verification engagement (sub-section 147(4)).

An intimidation or economic implications threat occurs when the verification body or a member of the verification team is deterred from acting objectively and exercising professional skepticism because of threats, actual or perceived, from the directors, officers or employees of the responsible party, and their impartiality is potentially threatened. For example:

- The threat of being replaced as third-party assurance provider due to a disagreement with the verification process;

- Fees from the responsible party represent a large percentage of the overall revenues of the verifier;

- The application of pressure to inappropriately reduce the extent of work performed in order to reduce or limit fees; or

- Threats arising from litigation with a responsible party.

1.7.3 Requirements for managing circumstances of conflict of interest

In preparation for a verification engagement, the verification body evaluates whether all members of the verification team, including subcontractors and outsourced verifiers, and the independent reviewer meet the applicable impartiality requirements. The person who submits an application or report is then responsible to inform the Minister whether a conflict of interest exists between them and the members of the verification team and/or the independent reviewer prior to starting verification activities (sub-section 145(2)).

In the event that there is a conflict of interest, the member of the verification team and/or the independent reviewer whose impartiality is threatened cannot perform any verification activities (sub-section 146(1)). If the conflict of interest in question can be managed, written evidence describing the actions that will be taken to mitigate the threat to impartiality must be provided to the Minister by the responsible party (sub-section 145(4)). The Minister will provide a response within 20 days of being informed of the threat to impartiality (sub-section 146(2)). Upon written notification by the Minister that they are satisfied that the conflict of interest can be effectively managed, the verification team and independent reviewer may proceed.

If a threat to impartiality develops during verification activities, the verifier determines and documents the actions required to mitigate the identified threat to impartiality and must notify the Minister within 5 days of the threat being discovered (sub-section 145(3)). That notice indicates the nature of the threat and the actions taken to mitigate it. The individual verifiers and the independent reviewer who are involved in the conflict of interest must stop any verification activities until the Minister's decision (section 146). Table 4 includes a non-exhaustive list of examples of threats to impartiality and the corresponding mitigation measures.

| Threat | Situation | Mitigation Measures |

|---|---|---|

| Self-Interest | A verification team member's spouse sits on the Board of Directors of the client. | The member of the board abstains from voting on any decisions involving the verification. |

| Self-Review | A person works at a firm and consults for a registered creator on a credit-creation report but later leaves to work for a verification body (and is onboarded on the verification team) that is hired to verify the same report that they consulted on originally. | The verification body would ensure that this person is not onboarded on any verification assignment (neither as a verifier nor as an independent reviewer) that implies the verification of any report from this regulatee until five (5) years has passed after the end of their previous role and the start of a verification. |

| Familiarity | The client invites the verification team to a sports game (i.e., soccer, hockey) in the corporate box. | The verification team provides compensation for the tickets. |

The verification body monitors their impartiality during the verification in accordance with ISO/IEC 17029, ISO 14065 and ISO 14066.

1.8 Values and ethics

Every member of a prime or outsourced verification body's verification team, including subcontractors, as well as the independent reviewers are expected to act with integrity and ethics in accordance with ISO 14066:2011 when conducting any verification activity under the CFR. It is the responsibility of verification bodies to ensure that measures are in place if any derogation from this moral obligation should be detected or suspected (in accordance with the ISO 17029:2019 requirement on responsiveness to complaints). ECCC reserves the right to bring to the attention of the verification body any demonstrated or suspected breach of this obligation and expects appropriate measures to be taken.

1.9 Records relevant to the verification body

Verification bodies must document and store the books and records related to verification activities that they performed for a minimum of ten years (sub-section 166(2)). In accordance with the requirements in ISO/IEC 17029 and section 134 of the CFR, these records include all the details listed in section 2.16 of this document.

1.10 Complaints mechanism

In accordance with the requirements of ISO/IEC 17029 related to the management of appeals and complaints, the verification body has a documented complaints mechanism to address cases of complaint, dispute, challenge, appeals and/or conflict filed about any element of its verifications.

As part of the complaints mechanism and in accordance with the ISO/IEC 17029 requirements, the verification body ensures that:

- The individuals who conducted any of the verification activities are not involved in the complaints-handling process;

- The confidentiality of the individual or organization filing a complaint and the subject of the complaint, when applicable;

- Transparent and timely communication with all the parties involved throughout the complaints management process;

- A formal notice of the outcome is issued to the complainant and ECCC.

1.11 Public information

In accordance with the requirements of ISO/IEC 17029 and ISO 14065, the verification body makes publicly available the fact that they are accredited to provide verification services under the CFR. Additionally, the verification body makes the following information available to stakeholders upon request, including:

- Verification activities in accordance with the CFR requirements;

- Compliance with the CFR requirements;

- Procedure for granting, maintaining, refusing and withdrawing verification services under the CFR;

- Process for the management of complaints;

- Personnel and committee members responsible for overall performance of its activities; policy matters; verification decisions; and resolution of complaints;

- Any active, unresolved, and resolved complaints related to the CFR verification.

2 Requirements relevant to the verification processes

2.1 Verification processes − applicable standards requirements

Verifications are conducted in accordance with the standard ISO 14064-3: 2019 - Specification with guidance for the verification and validation of greenhouse gas statements, which sets out the verification process at a reasonable level of assurance (paragraph 148(1)(a)).

For the verification of financial information (e.g., Compliance Credit Revenue Report, Compliance Report, or Complementary Compliance Report), the financial information must be audited at a reasonable level of assurance in accordance with the Canadian Audit Standards, the primary source of which is, in Canada, the CPA Canada Handbook —Assurance (sub-section 148(2)).

For the verification in relation to the Specifications for Fuel LCA Model CI Calculations (e.g., an application for the approval or temporary approval of a carbon intensity, and a carbon intensity pathway reporthe critical review of the life cycle assessment must be conducted in accordance with the most recent versions of the standard ISO 14044 - Environmental management — Life cycle assessment — Requirements and guidelines (sub-clauses 6.1 and 6.2) including the additional requirements and guidelines specified in the Technical Specification ISO/ TS 14071 Environmental management — Life cycle assessment — Critical review processes and reviewer competencies.

2.2 Frequency of verification

The frequency of verification for any annual regulatory report is annual. The frequency of verification of applications is on an as-submitted basis. Quarterly Credit Creation Reports are not subject to verification with the exception of the one-time combined Quarterly Credit Creation Reports (categories 2 & 3 for low CI fuels) for the compliance period that ends on December 31, 2022.

2.3 Level of assurance

The level of assurance required for all verifications, is reasonable (sub-section 148(1)). When an audit of financial information is part of the verification, the financial audit must be conducted at a reasonable level of assurance (sub-section 148(2)).

In verification, a reasonable level of assurance requires the verifier to design the verification to provide a high but not absolute level of assurance on historical data and information (ISO 14064-3:2019 3.6.6). Reasonable level of assurance differs from limited level of assurance verifications in the nature and extent of verification activities. Under reasonable levels of assurance, it is required that:

- risks be identified at the level of occurrence, completeness, accuracy, cut-off, and classification for emissions and removals; and existence, rights, obligations, completeness, accuracy and allocation for storage (ISO 14064-3:2019 6.1.2.2);

- evidence-gathering activities be designed for every material emission or removal (ISO 14064-3:2019 6.1.3.1);

- a data trail be established for every material emission, removal, and/or storage (ISO 14064-3:2019 6.1.3.2);

- in using detailed analytical testing, expectations are identified to determine if results are material and investigation of those material misstatements is undertaken by obtaining additional evidence (ISO 14064-3:2019 6.1.3.6.1);

- when relying on controls, evidence-gathering activities are designed to test the operating effectiveness of those controls (ISO 14064-3:2019 6.1.3.2);

- when using estimate testing, evidence-gathering activities are designed to test the operational effectiveness of the controls governing the development of the estimate and their own estimate or range is developed to evaluate the original estimate (ISO 14064-3:2019 6.1.3.6.3);

- when using detailed-level analytics, the analytics can detect material misstatements (ISO 14064-3:2019 6.1.3.6.1).

2.4 Criteria

The criteria for verifications are the applicable regulatory requirements set out into the Clean Fuel Regulations (paragraph 149(c)).

For the auditing of financial information (e.g., Compliance Credit Revenue Reports, Compliance Reports or Complementary Compliance Reports), the criteria to be used for the audit of financial information are International Financial Reporting Standard published by the International Accounting Standards Board, or the Accounting Standards for Private Enterprises published by Accounting Standards Board (“AcSB”) for private enterprises. These standards can be found in CPA Canada Handbook (“the Handbook”) in Part I and Part II respectively (paragraph 149(a)). When auditing financial information, particular attention should be paid to the accounts payable calculation and source documentation.

For the critical review of LCA information (e.g., Carbon Intensity Pathway Report or Application for the Approval of Carbon Intensity), the critical review must assess the general requirements set out in Section 6.1 of ISO 14044 (paragraph 149(b)).

2.5 Materiality thresholds

Materiality is the concept that individual misstatements or the aggregation of misstatements could influence ECCC's decisions. Materiality provides a minimum threshold that ECCC expects; the verifier uses professional judgement in determining materiality and may use values lower than specified in this document. Materiality has two components: quantitative and qualitative. Quantitative materiality thresholds are set out in sections 150 to 151 of the CFR.

Table 5: Use of Materiality

Verification

Materiality is used at two critical steps:

- During the design of evidence-gathering activities; and

- During the assessment of evidence.

2.5.1 Quantitative materiality thresholds

Quantitative materiality refers to misstatements in value in the GHG statement. Examples are presented in Appendix D and include calculation errors, incomplete inventories (e.g., omissions of material sources), and misclassified GHG emissions.

The regulations require that quantitative misstatements be aggregated to determine the total effect on the reported information during the assessment of evidence (sub-section 153(1)). Summing the misstatements provides ECCC with the effect on the final values.

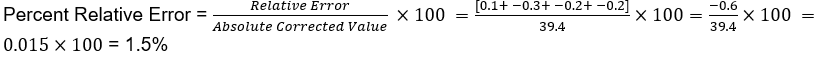

The calculations for relative error and percent relative error to be used to evaluate quantitative materiality are the following (sub-section 153(3)):

Long description

Relative error is the sum of errors, omissions, and misreporting. Percent relative error is the relative error divided by absolute corrected value multiplied by 100.

Relative Error: is the difference between the reported value and the corrected value. The difference is caused by errors, omissions, and misreporting.

Errors: are quantitative inaccuracies in the data.

Omissions: are incompleteness in the data that affect the value and can be corrected (e.g., missing sources in the inventory).

Misreporting: are misclassifications in the data. Misreporting can be quantitative and qualitative. In the error analysis, only the quantitative values of misreporting are used.

Percent Relative Error: is an expression of the error relative to the corrected value in percentage.

Corrected Value: is the value that has been adjusted by the errors, omissions, and misreporting found in the evidence.

Absolute Corrected Value: is the absolute value of the corrected value.

The overall quantitative materiality threshold that applies during the verification of regulatory reports and applications is 5% except for CI Values (paragraph 150(b)) because it experiences problems at small and large CI values.

For CI values:

At small absolute values, measurement systems have difficulty producing the degree of accuracy to measure the reported values (e.g., 5% of 0 g CO2e/MJ is 0 g CO2e/MJ which requires extreme measurement capabilities). Thus, for small CI values where measurement issues exist, a set value of 1 g CO2e/MJ is used (paragraph 150(a)(i)).

At large absolute values, a materiality issue can exist. For example, a low CI fuel can have values as low as -400 gCO2e/MJ. A 5% materiality threshold on 400 gCO2e/MJ (absolute) is 20 g CO2e/MJ which is a similar magnitude to many anticipated low-CI fuels. Thus, for large CI values where materiality issues exist, a set value of 5 g CO2e/MJ is used (paragraph 150(a)(iii)). The materiality thresholds that the CFR will accept for CI values are presented in Table 6 .

| CI Value (g CO2e/MJ) | Materiality Threshold |

|---|---|

CI=>100 |

5 gCO2e/MJ |

100>CI>=20 |

5% |

20>CI>-20 |

1 gCO2e/MJ |

-20=>CI>-100 |

5% |

CI=<-100 |

5 gCO2e/MJ |

Negligibility Thresholds and Materiality

The negligibility threshold is the level below which the contributions (e.g., sources or sinks) are clearly trivial to the reported value (e.g., carbon intensity value). The negligibility threshold is set low enough such that the aggregation of the clearly trivial contributions is lower than materiality. For the CFR, the negligibility threshold is set at 5% of the overall quantitative materiality (sub-section 153(2)). Thus, if the materiality threshold is 5 g CO2e/MJ, the negligibility threshold is 0.25 g CO2e/MJ. If the materiality threshold is 5% (e.g., for material balances and compliance credits), the negligibility threshold is 0.25%.

Rounding Protocols and Materiality

Rounding procedures must adhere to requirements set out in International Standard ASTM E29-22, Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications (sub-section163(1)). Rounding is used to clarify reporting and imply accuracy but should not obscure materiality. Under this standard, there are two acceptable rounding protocols (absolute and rounding methods), and the choice must be specified (ASTM E29-2, 4.1). Verifiers should be familiar with both rounding methods.

The absolute method considers all digits in an observed or calculated value to be significant.

The rounding method limits the number of digits in an observed or calculated value. The rounding methodology as specified by the standard is:

When the digit next beyond the last place to be retained is:

- <5, retain the last place digit;

- >5, increase the last place digit by 1;

- =5, if the last place digit is odd, increase the last place digit by 1;

- =5, if the last place digit is even, retain the last place digit.

For example:

- 59.4, to be rounded to the nearest 1, is 59

- 59.5, to be rounded to the nearest 1, is 60

- 59.6, to be rounded to the nearest 1, is 60

- 58.5, to be rounded to the nearest 1, is 58

The rounding interval selected is different depending on whether the value is a measure or test result. For direct measures, such as meter readings, dials, or scales, all digits known exactly plus one digit for estimation should be recorded. For test values, the rounding interval should be between 5% to 50% of the standard deviation.

Exceptions to the above standard are:

- Primary supplier’s reduction requirement – rounded to the nearest whole tonne of CO2e (sub-section 163(2));

- Approved carbon intensity – rounded to the nearest whole number (sub-section 163(3)); and

- Compliance credits – rounded to the nearest whole number (sub-section 163(3)).

In these cases, if the digit beyond the whole value is 5, increase the whole value by 1.

For example:

- 59.4, to be rounded to the nearest 1, is 59

- 59.5, to be rounded to the nearest 1, is 60

- 59.6, to be rounded to the nearest 1, is 60

- 58.5, to be rounded to the nearest 1, is 59

Rules for carrying significant digits:

Addition and Subtraction – the result contains no significant digits beyond the place of the last significant digit of any datum;

Examples:

11.24 + 9.3 +6.32 = 26.9

926 – 923.4 = 3

140,000 + 91,460 = 231,000 when the first value was recorded to the nearest 1,000

Multiplying and Dividing – the result contains no more significant digits than the value with the smaller number of significant digits;

Examples:

11.38 x 4.3 = 49

(926 – 923.4)/4.3 = 0.6

- Exact Counts (e.g. compliance credits) are treated as having an infinite number of significant digits.

Significance Threshold and Materiality

A significance threshold is used to determine when to restate values for events that happened after the fact, quantification methodologies that change, CI values that improve, facilities that change (expand), etc. The significance threshold is a reflection of materiality and the level of administrative burden the program is prepared to tolerate. The following significance thresholds in Table 7 below apply (section 156).

| Value | Significance Threshold |

|---|---|

CI Value |

Twice Materiality Thresholds |

Material Balances |

10% |

Production Values |

10% |

Credits |

2000 t |

Monetary Values |

10% |

2.5.2 Qualitative materiality thresholds

Qualitative materiality refers to intangible issues that affect the GHG statement. Examples include:

- report does not conform with criteria (e.g., land use or biodiversity criteria);

- validated criteria are no longer appropriate due to changing operational conditions;

- control issues that erode the verifier’s confidence in the reported data;

- unacceptable uncertainty in the reported data;

- poorly managed documented information;

- difficulty in locating requested information;

- inappropriate disclosure;

- non-compliance with the regulations indirectly related to GHG emissions, removals or storage.

Qualitative materiality is difficult to define and changes with time (e.g., new requirements, protected areas, etc.) and as such, the following section provides principles and examples of what ECCC would consider material but cannot be completely comprehensive. This guidance does not remove the responsibility from the verifier to exercise professional judgement on qualitative matters that may be material. Verifiers are required to assess any qualitative misstatements to determine if they are material (section 151) (ISO 14064-3:2019 s.6.3.1.3). If the verifier is uncertain, ECCC requires disclosure as a minimum course of action (Schedule 20(2)).

2.5.2.1 General principles

Verifiers are required to assess qualitative aspects of the application or report (section 151). The qualitative matter is material if the application or report does not:

- meet eligibility requirements;

- adhere to the criteria; and/or

- meet records requirements.

The following illustrates qualitative matters that are material according to the aspects listed above.

2.5.2.1.1 Eligibility requirements

Cases could be:

- Ineligible feedstock (sub-section 146(1), sections 48-55, 57, 58):

- Feedstock for a low-CI fuel that came from wildlife habitat;

- Feedstock that was cultivated in a manner that spreads or establishes damaging agents, such as pests, invasive species or disease);

- Feedstock that causes indirect changes to land use that adversely affect the environment;

- Feedstock that originated on excluded lands, such as forests, wetlands, grasslands or riparian zones;

- Forest-based feedstock for which the management plan does not promote timely regeneration of the land to pre-harvest conditions;

- Forest-based feedstock that has a management plan that does not ensure adverse effects on naturally generated stands, soil, surface or ground water, biodiversity, and connectivity of water courses.

- A fuel that does not have a sufficiently low enough CI value as defined by the CFR program (CFR Definitions – Low-carbon-intensity fuel);

- Projects that create compliance credits beyond 10 years of operating and producing compliance credits (paragraph 32(2)(d)).

Examples of eligibility issues that require careful consideration and likely disclosure by either the applicant/reporter or verifier:

- a portion of the feedstock that is not included in the quantification of the low-CI but came from a protected area (e.g. feedstock from a protected area is being harvested in conjunction with the eligible feedstock);

- a low-CI fuel feedstock is harvested in an area where a near-threatened species, but not yet vulnerable or threatened species, lives;

- the impacts of harvesting feedstock for a low-CI fuel that could impact water courses and riparian zones downstream from the harvest area;

- feedstock cultivated and harvested in a region with marginal environmental protection regulations that meets applicable legislation but would not meet similar Canadian requirements;

- feedstock cultivated and harvested in a region with no environmental protection regulations and a marginal management system that would not meet similar Canadian standards;

- feedstock that could have been used for food but allowed to become inedible in a region where starvation or food shortages are prevalent;

- there is a local movement to protect the area where the feedstock is harvested and could potentially change the eligibility of the harvest area in the future;

- continued harvesting of the feedstock in the same area will erode soil quality in the future.

2.5.2.1.2 Criteria Adherence

Cases could be:

- Failure to demonstrate that a project started its operation on or after July 1, 2017 (paragraph 35(1)(c));

- Projects that reduce the production of fuel by an operational or physical change (e.g., reducing facility throughput, shutting in wells, etc.) (paragraph 33(a));

- Misclassification of material amounts of:

- fuel

- feedstock

- electricity used instead of fuel (e.g., EV vehicles)

- credits

- Inability to demonstrate that a renewable fuel was used as a fuel in a vehicle in Canada (paragraph 19(1)(d));

- Use of a quantification methodology for a project that was not approved by the Minister (sub-section 37(3));

- Use of a CI value that was not approved by the Minister (sub-section 123(1));

- Not adhering to the applicable quantification methodology (sub-section 36(1));