Caring for feathers, quills, horn and other keratinous materials

Carole Dignard and Janet Mason

Caring for feathers, quills, horn and other keratinous materials is part of CCI’s Preventive conservation guidelines for collections online resource. This section presents key aspects of managing the care of keratinous materials in heritage collections based on the principles of preventive conservation and risk management.

Table of contents

- Understanding feathers, quills, horn and other keratinous materials

- Causes of damage to keratinous materials and preventive conservation strategies

- Examples of preventive conservation practices

- Bibliography

List of abbreviations and symbols

Abbreviations

- B.C.

- British Columbia

- CCI

- Canadian Conservation Institute

- ISO

- International Organization for Standardization

- portable document format

- RH

- relative humidity

- UV

- ultraviolet

Symbols

- cm

- centimetre

- metre

- metre

- Mlx∙h

- megalux hour

- nm

- nanometre

- µW/lm

- microwatt per lumen

Understanding feathers, quills, horn and other keratinous materials

This resource describes the nature and use of feathers, porcupine quills, horn and other keratinous materials in heritage collections. Although fur and wool are also keratinous materials, they are covered instead in Caring for leather, skin and fur and in Caring for textiles and costumes, respectively.

Keratinous materials

Feathers, hair, porcupine quills, horn, baleen, claws, hooves and tortoiseshell are very different in form and visual appearance, yet they are similar in nature: they are all keratinous materials arising from the epidermis, or outer surface layer of skin, of animals (Figure 1). Keratin acts as a tough yet resilient outer coat that protects the animal from its environment.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0055

Figure 1. Examples of keratinous materials. Clockwise from the top: baleen, hair, tortoiseshell, porcupine quills, a horn and a feather. In the centre: a deer hoof claw.

Generally, keratinous materials are not very susceptible to chemical degradation. They are known for their resistance to water, solvents, acids, alkalis and enzymes. They are resilient, so they can flex to some degree without breaking. In practice, many keratinous materials are relatively malleable and can be shaped or molded by heat.

Feathers

There are two basic types of feathers: pennaceous and plumulaceous. Pennaceous feathers or contour feathers refer to long feathers covering the bird’s body, wings and tail. They consist of a hollow quill (calamus) at the base that turns into a shaft with a spongy core (rachis) extending from the base to the tip, from which two sets of barbs project out on each side. Barbs, in turn, support two sets of barbules that are attached to each other by means of hooklets or barbicels, thus allowing the feather’s structure to completely interlock to form the vane of the feather. This structure is water-repellent and can provide lift to allow flight.

Down feathers are the most common type of plumulaceous feathers. They have barbs and barbules that do not interlock and, as such, cannot produce a vane. The barbs form dense fluffy tufts which trap air and provide excellent insulation.

Peacock feathers can be considered as a special type of feather because they have a specific and unique morphology. Figure 2 shows examples of various feathers.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0054

Figure 2. Six feathers of different natural colours. The third one (from the left to right) is a common white feather with both a pennaceous portion at its top (with interlocking barbules) and a fluffy plumulaceous portion on the bottom section (non-interlocking). The two feathers on the left as well as the peacock feather (second from the right) show examples of blue and green structural colours.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0056

Figure 3. A feather headdress from Brazil, probably made of parrot or macaw feathers. The blue in the long feathers is a structural colour.

A feather may be coloured by natural pigments or by structural colours (Figures 2 and 3). Structural colors, which may be iridescent like those on a peacock feather, are the result of interference effects when light interacts with special thin microstructures. A white feather has no pigmentation. Feathers can also be dyed.

Feathers have been used in many cultures as decorative elements on such objects as hats and headdresses (Figures 3, 4 and 5), clothing, musical instruments (rattles, drums), fans and bags. In North American Indigenous cultures, some objects made of feathers may be culturally sensitive and, hence, require special care (consult Caring for sacred and culturally sensitive objects). Traditionally, feathers were used as a writing instrument for ink. They are also used to make arrows and shuttlecocks and as insulating layers in clothing, pillows, quilts and mattresses.

© Government of Canada, Canadian Conservation Institute. CCI 79409-0015

Figure 4. A Mi’kmaq feather headdress. This object belongs to the McCord Museum (accession number: M122).

© Catherine Mathias, PhD

Figure 5. Black fur cocked hat with white ostrich feather border. The hat was owned by Sir Samuel Hughes, Canadian Minister of Militia and Defence during the First World War.

Porcupine quills, hair and bristles

Hairs and bristles are composed of a characteristic root and a shaft. Coloured hairs contain melanin pigments.

Porcupine quills are essentially specialized hairs, and it is estimated that a mature porcupine has about 30,000 of them. They vary in length from 1 cm to as much as 15 cm. They can be creamy white, brown or a mixture of the two colours (Figure 6). They are sometimes used undyed (Figure 7) but more often coloured with natural or synthetic dyes.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0033

Figure 6. Porcupine quills (top left) compared to moosehair (bottom) are generally shorter and thicker. The first four quills on the left are undyed, showing their natural cream colour with dark brown-coloured tips. The eight other quills and the moosehair are dyed.

Porcupine quills are found extensively on Indigenous clothing and domestic items, such as baskets, birchbark containers (Figure 7), bags, vests, jackets (Figure 8), moccasins, belts and headdresses. “Quillwork” refers to the patterned assemblies of flattened and folded quills stitched into or onto a skin or birchbark base (such as on the back and shoulder area of the jacket in Figure 8). Quills are also used simply twined around a base, such as around basketry strands or skin fringes (as shown at the base of the fringes in Figure 8).

© Government of Canada, Canadian Conservation Institute. CCI 125773-0030

Figure 7. Detail of a birchbark and sweetgrass container with undyed porcupine quill decorations.

© Government of Canada, Canadian Conservation Institute. CCI 96557-0048

Figure 8. Detail of quillwork decoration on a skin jacket. The jacket was given to James Anderson in 1847 by a First Nations group, probably the Cree, while he was working at a Hudson’s Bay Company post at Lake Nipigon.

Moosehair is found embroidered onto various objects, such as birchbark containers and buckskin clothing items, in a similar way to porcupine quillwork (Figure 9). Moosehair is usually recognizable because it is thinner than a porcupine quill (consult Figure 6); as such, moosehair embroidery is typically finer and more delicate than porcupine quillwork. Moosehair can also be distinguished by its morphological characteristics. Moosehair and hair from other members of the deer family, such as caribou, are also used for tufting embroideries. In addition, tufts of moose, caribou and horsehair may be used as decorative tassels, usually dyed and sometimes enclosed within metal cones (Figure 9).

© Government of Canada, Canadian Conservation Institute. CCI 2003901-0002

Figure 9. Moosehair embroidery and decorative tassels on a knife sheath. This object belongs to the Canadian Museum of History (accession number: III-H-13).

Animal hair and bristles may be found as decorative elements on masks, headdresses and other similar items (Figure 10), or they may be used to replicate human hair on dolls. Human hair may also be found in museum collections, as it was used to make wigs as well as Victorian wreaths and hair jewellery. Horsehair was commonly used as stuffing for upholstered furniture such as sofas, chairs and vehicle seats.

© Government of Canada, Canadian Conservation Institute. CCI 98010-0008

Figure 10. Sea lion whiskers decorate the top of this Yaxwiwe’ forehead frontlet (i.e. headdress made of a wooden mask with an attached fur head covering) owned by the U’mista Cultural Centre in Alert Bay, B.C. Sea lion whiskers are used as decorative elements by the Kwakwaka’wakw, Namgis, Haida, Tlingit and other Indigenous peoples of North America.

Consult Caring for leather, skin and fur for further information on fur and Caring for textiles and costumes for further notes on wool.

Horn

Sheep, goats, antelopes, oxen and other bovids have horns, which consist of keratinous material growing over two underlying bony cores on the animal’s skull. New tissue is added in a periodic manner to the base of the horn, and this gives it its characteristic ridged appearance. Horn should not be confused with antler, which is a bony material in animals of the deer family.

A variety of objects made wholly or partly of horn can be found in museums. Horn can be used virtually unmodified for containers and as sounding horns; it can be carved and shaped to make such items as spoons (Figure 11), ladles, fans, jewellery, buttons, eyeglass frames, combs and hairpins; it can be turned into gaming pieces and handles; it is also used in sheets to create marquetry on furniture, usually stained or coloured to mimic tortoiseshell. Since very early times, it has been worked and molded into various shapes using heat, often by immersion in boiling water. It then becomes flexible enough to be formed into quite complex shapes. It can be cut longitudinally, opened out and pressed into molds or between hot iron plates to form thin flat sheets. These sheets can be further split into leaves by exploiting horn’s natural tendency to delaminate.

In the 19th century, techniques were developed for reforming powdered horn into various relatively complicated shapes by combining the powder with strong alkalis and using molds with heat and pressure. The resultant objects, such as snuff boxes (Figure 12) or knife handles, in no way resemble the original form of the horn, yet they retain its smooth and shiny surface appearance.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0053

Figure 11. Horn can range in colour from yellow to brown to black. From right to left: a polished horn, three horn spoons of different sizes and a horn necklace.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0045

Figure 12. Snuff boxes made of molded horn.

Tortoiseshell

Tortoiseshell comes from the keratinous plates (or scutes) covering the bony carapace of certain species of marine and land turtles, most notably the hawksbill sea turtle, currently an endangered species. During their growth, the plates are laid down in thin sheets of 1.5 to 3.5 mm in thickness. The plates can be detached from the carapace by heating. Tortoiseshell has a distinctive and prized mottled appearance blending red, yellow and brown tones, with the colour varying between species.

Tortoiseshell is more homogeneous than horn; it is not fibrous and not as easily delaminated. The material is often used without further preparation; it is simply dried out, scraped clean and polished. Like horn, tortoiseshell can be heat-formed into quite complex shapes; it becomes pliable when boiled and can be pressed, molded and fused together. In the past, tortoiseshell was extensively used in combination with brass for marquetry work on furniture and clocks (Figure 13). It was also used, as horn was, to make combs, eyeglass frames, small boxes and various other items.

© Government of Canada, Canadian Conservation Institute. CCI 2005059-0002

Figure 13. Side view of a clock showing marquetry made of brass and tortoiseshell known as “Boulle work.”

The high price of tortoiseshell spurred its imitation, originally using horn but later celluloid (cellulose nitrate) and, more recently, other, more stable plastics. Examples of early plastic imitations of tortoiseshell are often found in museum collections (Figure 14). Consult Caring for plastics and rubbers for information on plastic imitations in heritage collections.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0058

Figure 14. Unpolished natural tortoiseshell (bottom left) compared to two examples of plastic imitations: a sample of marquetry work (top) and a comb with its slip-in case (bottom right).

Claws, beaks and hooves

Claws, beaks and hooves are sometimes found as decorative elements on objects, as elements of jewellery and ornamentation or as parts of musical instruments, such as rattles. Like horn, they are a hard keratinous outgrowth that is continually replaced from the epidermis. Cattle hoof is usually thinner and more pliable than horn.

Baleen

BaleenFootnote 1 consists of horny plates ending with bristles that function as filters, found in the mouths of certain whale species (baleen whales). The material is off-white, brown, blue or black in colour and from 50 cm to 3 m in length (Figure 15). It is composed of a sandwich of keratinous tubes surrounded by a cementing material within two sheathes of horn-like material. This complex structure is worn away at the tips by the action of the whale’s tongue, producing a fringe of tubes (bristles) that acts as a filter for plankton.

Baleen is used by the Indigenous peoples of North America to make ornaments, tools or containers (notably Alaskan woven baleen baskets). In the 18th and 19th centuries, it was used in Europe for such items as parts of ladies corsets, umbrella ribs, springs in musical instruments and the shafts of buggy whips. Baleen can also be used to make small boxes or buttons in a similar way to horn.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0051 and inset 125773-0052

Figure 15: A piece of unworked, black baleen and, in inset, an earring made of polished black baleen.

Caution: risk of pesticide residues

Because feathers, hair and fur, porcupine quills and other keratinous materials are prone to insect infestation, toxic insecticides might have been applied in the past, in some museums, to objects made of these types of materials.

Residues of these pesticides may be present on the surface of objects (Figure 16) or on adjacent surfaces (e.g. inside storage cabinets). Residues may be visible or invisible. Gloves and standard personal protection equipment (e.g. lab coat, safety glasses) should be worn when handling keratinous-based objects.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0112

Figure 16. White deposits such as these on feathers, hair or fur should be treated as pesticide residues, unless known to be otherwise.

Causes of damage to keratinous materials and preventive conservation strategies

In general, the thicker, harder keratinous materials such as horn, baleen, beaks, claws, hooves and tortoiseshell are more resistant, more durable or less reactive to agents of deterioration than the thinner, lighter, more delicate keratins such as feathers, hairs and porcupine quills. The following agents of deterioration are of specific concern for objects that are comprised of keratinous materials.

Physical forces

Damage due to various physical forces is generally a medium to high risk for keratinous materials.

Although horn, tortoiseshell, claws and hooves, and baleen are not extremely fragile, physical damage such as chips, cracks and breaks can occur if they are subject to stresses or impacts (Figure 17). Also, abrasion damage is not uncommon, especially on keratinous objects having flat surfaces.

© Government of Canada, Canadian Conservation Institute. CCI 2004388-0001

Figure 17. A horn ladle broken in two pieces and cracked that was probably damaged by accidental impact during handling.

Horn, tortoiseshell and baleen are made of layers that have a tendency to delaminate. They can also have rough edges. Both can cause a risk of snagging on dust cloths during dusting or on cotton gloves during handling.

Quillwork and moosehair embroidery are typically at medium to high risk of being physically damaged. For example, they may offer uneven, protruding surfaces that pose a risk of snagging if inappropriately handled. The quills and hairs that are bent within a quillwork or moosehair embroidery or that are wrapped around another element are under stress, and this makes them more at risk of breaking if subjected to additional stress when dusted or handled. Partially broken and lifting quills and moosehair are especially vulnerable to physical damage (Figures 18 and 19), as well as quills and hair that are deteriorated or have become brittle.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0113

Figure 18. The quills wrapped around strips of hide on this sash are extensively damaged and unravelling. They are at high risk of further damage during handling. Unstable environmental conditions (relative humidity [RH] and temperature) will exacerbate the unravelling.

© Government of Canada, Canadian Conservation Institute. CCI 96557-0009

Figure 19. It is not uncommon to find a few chipped, gnawed or lifting quills on quillwork that may appear at first sight to be in good condition (this image shows a detail of the jacket shoulder panel shown in Figure 8). There is a risk of snagging in these areas during handling.

Given their delicate structures and the volume they occupy, feathers can be inadvertently compressed, misshapen, bent or broken due to improper handling or overcrowded storage (Figures 20a to 20e). Abrasion damage on the surface of feathers with structural colours may result in the loss of these colours.

© Government of Canada, Canadian Conservation Institute. CCI 2005304-0001

Figure 20a. Buffalo hide warshield with red wool apron decorated with metal tinkle cones and feathers.

© Government of Canada, Canadian Conservation Institute. CCI 2005304-0002

© Government of Canada, Canadian Conservation Institute. CCI 2005304-0003

Figures 20b and 20c. Close-up of feathers, showing broken shafts.

© Government of Canada, Canadian Conservation Institute. CCI 2005304-0004

Figure 20d. A rectangular platform was made to physically protect the three feathers attached to the warshield’s perimeter during handling and storage. Individual supports for the central hide portion and for the three feathers are fixed to the platform.

© Government of Canada, Canadian Conservation Institute. CCI 2005304-0005

Figure 20e. Side view of the warshield on its support. Each feather is secured onto a foam pad support covered with jersey knit.

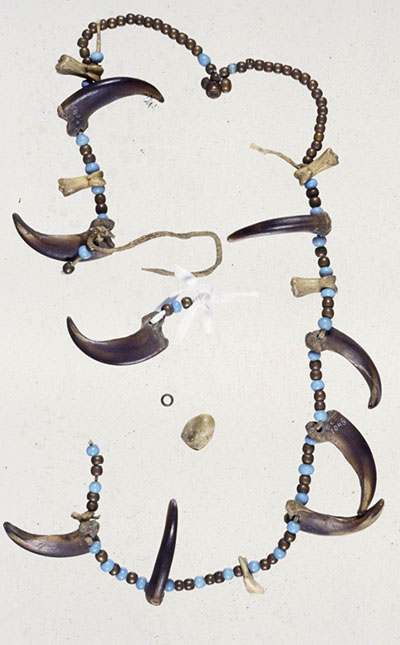

Claws, beaks and hooves are used to make necklaces as well as ornaments attached or affixed with thread, string, skin thongs or sinew to an object (Figures 21a and 21b). Hair bundles and feathers are also used in this way on masks or other objects of apparel, sometimes crimped into small metal cones (Figure 9). These decorative elements are at risk of detachment and loss during handling, transportation and relocation if the thread, string, sinew or skin thong that attaches them to the object is worn or damaged (Figure 21a). They may also be accidentally pulled off the object if left unsupported (dangling) during handling.

© Government of Canada, Canadian Conservation Institute. CCI 2005278-0001

Figure 21a. A Sarcee bear claw necklace. The hide string is broken, resulting in dethreading of some of the beads and claws, as well as losses.

© Government of Canada, Canadian Conservation Institute. CCI 2005278-0002

Figure 21b. The Sarcee bear claw necklace after conservation treatment, before being secured with ties onto a padded support. This object belongs to the McCord Museum (accession number: 1045.1).

Recommendations

- Build display and storage mounts that will support the objects over the long term and guard against slow deformation due to the effects of gravity.

- Provide sufficient storage space for objects decorated with feathers or sea lion whiskers to prevent compressing or kinking (Figures 20d, 20e and 22).

- Provide padding, boxes and securing ties for fragile objects on storage shelves or in drawers (Figures 22, 23, 24a and 24b).

- Ensure no fringe, tinkle cone or other such decorative element hangs from storage shelves. Provide supports, trays or boxes for handling and storing objects decorated with tinkle cones, fringes and other such attachments (Figures 23, 24a and 24b). Inspect fringes and hanging decorative elements to identify whether threads, strings and other means of attachments are weak or damaged and likely to break during handling and relocation. If necessary, secure them to reduce their movement, e.g. by immobilizing or wrapping them with twill tape.

- Identify damaged objects, and provide them with a padded support.

- As a general rule, move objects in boxes or on bases so as to avoid direct handling.

- Handling with clean bare hands or with cotton gloves is an option, but only for objects known to be pesticide-free. Because of the high risk of pesticide contamination, nitrile gloves and protective lab wear should be worn until the material is shown to be free of contamination.

© Government of Canada, Canadian Conservation Institute. CCI 2004113-0001

Figure 22. Feather hat protected from dust and risks of physical damage with a plastic-covered frame. A foam inner support raises and pads out the base of the skin hat.

© Government of Canada, Canadian Conservation Institute. CCI 2004476-0001

Figure 23. A knife sheath with long quill-wrapped fringes on a storage support that secures the decorative fringes, which would otherwise be at risk of catching and being damaged when handled or moved in storage.

© Government of Canada, Canadian Conservation Institute. CCI 2004257-0001

Figure 24a. A moose hoof pouch. The hoof is heavy and needs to be supported to prevent damage. This object belongs to the Canadian Museum of History (accession number: III-H-466).

© Government of Canada, Canadian Conservation Institute. CCI 2004257-0002

Figure 24b. The pouch is supported and fitted within a contoured recessed foam and secured with twill tape ties.

Water

Keratinous materials such as feathers, hair and quills are by nature resistant to water when undamaged. However, when these materials are placed decoratively onto objects, they are usually constrained (glued, tied, stitched) or physically altered (scored, crimped, bent or punctured) to create various design elements or points of attachment onto a textile, bark or basketry base; the resulting composite object is therefore, in general, vulnerable to water damage. Glued tortoiseshell marquetry is a good example of such a high risk material. Damaged materials such as those worn through use, or attacked by insects, have increased vulnerabilities. If the keratinous materials are dyed, there is furthermore the risk that water exposure could cause stains as well as the bleeding of colours.

For further information on general issues concerning the risks of water damage and prevention, consult Agent of deterioration: water as well as the section Incorrect relative humidity.

Pests

All objects made wholly or partly of keratinous materials should be considered at very high risk of insect infestation. Feathers, quillwork, fur pelts and hair are especially vulnerable (Figures 25, 26a and 26b), similarly to wool, which is also keratin-based (consult Caring for textiles and costumes). The thicker, harder keratinous materials are generally less at risk but can also be attacked.

© Government of Canada, Canadian Conservation Institute. CCI 79409-0003

Figure 25: Detail of insect damage to feathers on a headdress.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0114

Figure 26a. Detail of a moccasin with insect damage to the decorative quillwork and to some of the caribou hair tufts.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0115

Figure 26b. Detail of Figure 26a, showing characteristic insect bite marks on the blue porcupine quills. Often, insects preferentially attack quills dyed a specific colour.

Dermestids (notably carpet beetles) and clothes moths (casemaking and webbing clothes moths) are the main culprits of insect infestations of keratinous materials. Stained or dirty objects may be more at risk. The shape of the object or the way it is stored may also increase the risk by providing a safe haven, since insects can conceal themselves in recesses or under layers where there is less light. Objects left undisturbed in storage for extended periods are also prime targets.

Because keratinous materials are so prone to insect infestations, they were often treated with pesticides in the past. It is safest to treat these objects as potentially contaminated and to wear personal protective equipment, such as gloves, during handling (consult Caution: risk of pesticide residues).

Keratinous materials can also be attacked by mould; this is discussed further under Incorrect relative humidity.

Recommendations

- Identify, examine and document the most vulnerable objects (i.e. objects containing fur, hair, quills and feathers) to provide a reference for their periodic inspection.

- Implement an integrated pest management program.

- Inspect a random selection of vulnerable objects twice a year (in the spring and fall) to determine if they are infested.

- Consider providing cold or anoxic storage for fur and feathered objects to protect them from insect infestation.

If cold storage is used, ensure strategies are in place to promptly address any power failure or equipment failure that could lead to high RH and the risk of mould growth.

Pollutants

Dust, soiling and oily deposits are particularly a concern for quillwork, hair and feathers because these materials have complex topographies that can trap particulates and oily residues. Cleaning can therefore be difficult and disruptive to fine structures (Figures 27 and 28). Dust particles, in conjunction with RH fluctuations, can be abrasive, causing physical damage such as weakening, especially to the thinner or more delicate keratins like hairs and feathers.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0096

Figure 27. An example of soiled white feathers on a bird wing used to make a fan. The brown shading and blotches on the feathers are dust, soiling and oily deposits.

© Government of Canada, Canadian Conservation Institute. CCI 96557-0018

Figure 28. Detail of soiled quillwork. Cleaning will require treatment by a trained conservator.

Recommendations

- Protect objects from dust by using wrapping materials, boxes, dust sheets, closed storage units and display cases.

- Consider providing enhanced dust protection using positive pressure for selected objects most at risk in closed storage cabinets and display cases.

Light and ultraviolet

The natural pigments in such keratins as horn, tortoiseshell, feathers, quillwork and other hairs are, generally, moderately to highly light-sensitive, while natural and synthetic dyes used to colour these materials are, typically, highly light-sensitive (Figures 29a, 29b and 30; Table 1). Dark animal hair can become light-bleached to a paler, even blond, colour; brilliant reds in feathers can fade to pale and blander pinks, oranges or yellows. Structural colours on feathers can also be affected by light since some of these colours are due to interference effects associated with natural melanin pigment granules (Hudon 2005).

© Government of Canada, Canadian Conservation Institute. CCI 125773-0095

Figure 29a. Dyed quillwork on a fur object, showing extensive light fading.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0094

Figure 29b. The hairs shielding the edges of the quillwork are pushed away, revealing the quillwork’s vibrant original colours that were protected from light.

| Sensitivity of colours found on keratinous materials | Visible light level | TimeTable footnote 1 for just noticeable fadeTable footnote2 | |

|---|---|---|---|

| With UVTable footnote3 | No UVTable footnote 4 | ||

|

High: Some natural bright colours (some reds, oranges, greens and blues), plus colours obtained from most synthetic and natural dyes |

30,000 lux (average daylight) | 0.8 to 7 days | 1 to 14 days |

| 5000 lux (light from a window or study lamp) |

4 days to 1 month | 5 days to 2 months | |

| 500 lux (office lighting) | 5 weeks to 1 year | 7 weeks to 2 years | |

| 150 lux | 20 weeks to 3.5 years |

6 months to 7 years |

|

| 50 lux | 1 to 10 years | 1.5 to 20 years | |

|

Medium: Natural brown-toned colours |

30,000 lux (average daylight) | 5 days to 10 weeks | 2 weeks to 1 year |

| 5000 lux (light from a window or study lamp) | 3 weeks to 17 months | 2 months to 7 years | |

| 500 lux (office lighting) | 8 months to 14 years | 2 to 70 years | |

| 150 lux | 2 to 40 years | 7 to 200 years | |

| 50 lux | 7 to 140 years | 20 to 700 years | |

Note: Table 1 is based on Tables 3 and 4 in CCI’s Agent of deterioration: light, ultraviolet and infrared.

Table 1 summarizes the sensitivities of coloured keratinous materials to visible light with and without UV and provides estimates of the number of days, months or years to cause fading as a function of different light exposure scenarios. As can be seen in Table 1, if the light levels are reduced, for example from 5000 lux to 50 lux, this will prolong the enjoyment of colours by a factor of 100; if, instead, only the UV is filtered out of the light (compare the third column “With UV” to the fourth column “No UV”), this will have a beneficial but much more limited effect. Note, however, that all light exposures count—that is, any exposure causes some fading that accumulates over time. Because of this, if continuously displayed even at a mere 50 lux, highly sensitive colours may still visibly fade within a few years and moderately sensitive colours, within a few decades. This is why limiting exposure times is also very important to preserve sensitive colours as long as possible.

Furthermore, UV radiation can cause photodegradation of keratin, and especially of thinner materials such as feathers, moosehair and porcupine quills, which can lead to their weakening or embrittlement. Damage will occur sooner if photosensitizing dyes or components are present. Table 2 compares the effects of exposure to high or low quantities of UV: with proper light controls, damage can be significantly reduced and take centuries or millennia to occur.

|

Lighting |

UV contentTable footnote 3 |

Visible lightTable footnote 3 |

Medium sensitivity | High sensitivity |

|---|---|---|---|---|

| Weakening and eventual fragmentation of keratinous materials | Weakening and eventual fragmentation if photosensitizing dyes or components present | |||

| Daylight through window glass | ~400–500 μW/lm | Full daylight: 30,000 lux | ~3 years or more | ~2 months or more |

| 50 lux | ~2000 years or more | ~100 years or more | ||

| Daylight through window glass with good UV filter | ~75 μ/lm or less | Full daylight: 30,000 lux |

~30 years or more | ~2 years or more |

| 50 lux | ~many millennia (thermal agingTable footnote 4 likely in 100–1000 years at 20°C) | ~many millennia (thermal agingTable footnote 4 likely in 100–1000 years at 20°C) | ||

| Dark | No UV | none | (thermal agingTable footnote 4 likely in 100–1000 years at 20°C) | (thermal agingTable footnote 4 likely in 100–1000 years at 20°C) |

Note: Table 2 is based on Table 5 in CCI’s Agent of deterioration: light, ultraviolet and infrared.

Recommendations

- Identify sensitive objects and limit exposure and duration; all coloured quillwork and feathers other than natural browns (melanin) may be assumed to be in the high-sensitivity range.

- Use low light levels (50 lux) for all dyed or brightly coloured material. As shown in Table 1, fading will take much longer to occur at these levels compared to the rate at higher levels. Avoid exposures at high light levels (e.g. office lighting, study lamps and especially windows and daylight), since they will cause fading within weeks or even days (Table 1).

- Use 150 lux for non-dyed materials of natural brown tones (or any other material considered to be in the medium light-sensitivity category).

- Filter UV radiation emanating from light sources to less than 75 microwatt per lumen. As shown in Table 2, the benefits can be immense, e.g. even at 50 lux, if the UV is not filtered, physical damage could occur within years instead of millennia. Colours will also last longer, as shown in Table 1.

- Make displays of sensitive items temporary. Since light damage is cumulative, ration the total exposure time. Keep some representative objects out of the rotation so that they remain pristine indefinitely, for future research and to make facsimiles.

- Because each exposure to light is a step closer to fading (i.e. light damage is cumulative), it is useful to calculate light doses for sensitive objects planned for display and to keep track of these doses. To do this, keep a log of the total length of time the object will be exposed to light, as well as the light levels (in lux) and UV levels used. By calculating the cumulative exposure dose and by comparing this to the “Maximum Cumulative Exposure Dose” (Table 3), it is possible to assess display options over the long-term in terms of the cumulative risks to the object. Consult Agent of deterioration: light, ultraviolet and infrared – Control of light, UV and IR for more details.

- Use timers and similar systems for providing light on demand during short intervals.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0116

Figure 30. Detail of the lid of a quilled birchbark container. The quills in the middle lozenge pattern were initially dyed red but are now faded to a pale pink or cream colour.

| Maximum cumulative exposure doseTable footnote 1 | |||

|---|---|---|---|

| Medium sensitivityTable footnote * | High sensitivityTable footnote ** | ||

| Dose for just noticeable fade: | if UV present | 3.5 to 20 Mlx∙h | 0.22 to 1.5 Mlx∙h |

| if UV removed | 10 to 100 Mlx∙h | 0.3 to 3 Mlx∙h | |

Note: Table 3 is based on Table 4 in CCI’s Agent of deterioration: light, ultraviolet and infrared.

Incorrect relative humidity

Although new keratinous materials are generally resistant to RH fluctuations and extremes, these conditions should, in general, be avoided in museum collections, as they can lead to problems for certain types of objects. In particular, keratinous materials fixed to other materials may be exposed to a medium to high risk of damage at their point of attachment or restraint (Figure 31). Examples of restrained keratinous materials include tortoiseshell or horn sheet inlays glued down to a base material to form marquetry patterns, as in Figure 13; the material may also be restrained by being tied down, stitched, wrapped, coiled or embroidered onto a base. If exposed to damp or subject to large RH changes, the base materials or the attaching threads may swell or shrink at different rates than the keratinous material, which would lead to tensions and possibly to cracks or fractures. Thin keratinous materials, or those that are worn or otherwise already damaged or deteriorated, are at a higher risk of damage. Porcupine quills and moosehair in embroideries may split, break or lift (Figure 31); horn or tortoiseshell marquetry may lift, buckle or crack; and feather shafts may become damaged at their point of attachment to the substrate.

© Government of Canada, Canadian Conservation Institute. CCI 125773-0097

Figure 31. Detail of a quilled band showing physical damage to some quills, such as splitting and curling. Changes in the climatic conditions can lead to further damage.

Above 65% RH, mould can grow. Consult Agent of deterioration: incorrect relative humidity, which provides a chart indicating the rate of mould growth by humidity level. Keratinous materials are generally at low risk of being attacked by mould. However, mould is a moderate to high risk for many of the other materials that typically make up the objects upon which keratinous materials are found: skin, leather, textiles, cotton threads and strings, as well as plant fibres on basketry. In the event of a power shortage or equipment failure, mould growth is a risk to furs and feathers stored in cold rooms. This long-term risk must be taken into account when assessing cold storage (consult Caring for leather, skin and fur – Furs: cold storage versus anoxic storage for an example).

Recommendations

- Implement strategies to prevent water ingress or moisture in the museum and any exposure to water or dampness.

- Implement climate control strategies to prevent high RH (65% or higher) or large humidity fluctuations.

- In storage, wrap or cover sensitive objects with humidity-buffering materials such as cotton or acid-free tissue—being careful not to create risks of snagging when dealing with objects with broken and lifting quills or with other elements similarly damaged. Place wrapped objects in enclosures such as polyethylene plastic bags, matboard or fluted plastic boxes, or in closed cabinets to further help slow down and buffer changes in RH. The more layers and enclosures provided, the better the protection.

- If cold storage is used (sometimes used to prevent infestations, notably for objects made of furs and feathers), ensure that all objects are enclosed in airtight bags or boxes and that strategies are in place to promptly address any power failure or equipment failure that could lead to high RH.

Examples of preventive conservation practices

Mount and protective structure for a feather headdress

The storage mount for the head portion of an eagle feather headdress (Figure 32) was made of a piece of carved polyethylene foam covered with polyester batting and cotton jersey knit (Figure 33). A box made out of a wooden frame covered with plastic sheeting allowed for full viewing, while providing dust protection as well as physical protection against accidental encroachment during storage.

© Government of Canada, Canadian Conservation Institute. CCI 2004409-0001

Figure 32. An eagle feather headdress without any mount, laying on its side.

© Government of Canada, Canadian Conservation Institute. CCI 2004409-0002

Figure 33. A storage mount and dust protection box for an eagle feather headdress.

Storage protection for an ornate pair of moccasins

Problem:

A pair of moccasins (Figure 34a) decorated with glass beads, quillwork and quill-twined skin fringes was susceptible to physical damage and to the loss of small parts during handling and displacements. Some of the small decorative elements were loose or damaged (Figures 34b, 34c and 34d).

© Government of Canada, Canadian Conservation Institute. CCI 72913-0002

Figure 34a. Overall view of a decorated pair of Plains Indian moccasins. This object belongs to the McCord Museum (accession number: 12609.1-2).

© Government of Canada, Canadian Conservation Institute. CCI 72913-0005

Figure 34b. Detail of a moccasin, showing partly loose and missing twined quills.

© Government of Canada, Canadian Conservation Institute. CCI 72913-0004

Figure 34c. Detail of a moccasin, showing damaged quills due to insect attack.

© Government of Canada, Canadian Conservation Institute. CCI 72913-0003

Figure 34d. Detail of a moccasin, showing damaged beadwork at the heel area.

Solution:

Treatment carried out at CCI included securing the damaged beadwork and quills. The moccasins were padded with inner supports, set onto a padded base and then placed into a storage box with a window lid (Figure 34e). The box provides protection against physical forces and any potential accidental loss of small components during handling. It also shelters against dust, water and soiling and, to some degree, against sudden RH changes. It was made of fluted plastic sheet and twill tape ties. The top has a transparent Melinex plastic sheet window that allows for easy identification and viewing.

© Government of Canada, Canadian Conservation Institute. CCI 72913-0001

Figure 34e. Moccasins in storage box.

Bibliography

DeMouthe, J.F. Natural Materials: Sources, Properties and Uses. Burlington, MA: Elsevier Butterworth-Heinemann, 2006.

Hudon, J. “Considerations in the Conservation of Feathers and Hair, Particularly Their Pigments.” Fur Trade Legacy: The Preservation of Organic Materials, Preprints from the Workshop at the 31st Annual Conference in Jasper, Alberta, 17–18 May 2005. Ottawa, ON: Canadian Association for Conservation of Cultural Property, 2005, pp. 127–147.

National Park Service. Storage Mounts for Feathered Headdresses and Soft-Sided Hats and Caps (PDF format). Conserv O Gram 5/2. Washington, D.C.: National Park Service, July 1993.

Pedersen, M.C. Gem and Ornamental Materials of Organic Origin. Burlington, MA: Elsevier Butterworth-Heinemann, 2004.

Reuss, M. “Imitations Made From Early Plastics as Trade Goods.” Preprints of the ICOM-CC 12th Triennial Meeting, Lyon, 1999, vol. 2. London, UK: James & James, 1999, pp. 596–601.

Stone, T. Care of Ivory, Bone, Horn and Antler, revised. CCI Notes 6/1. Ottawa, ON: Canadian Conservation Institute, 2010.

Stone, T., C. Dignard and J. Mason. Care of Quillwork, revised. CCI Notes 6/5. Ottawa, ON: Canadian Conservation Institute, 2010.

Storch, P.S. “Quills, Horn, Hair, Feathers, Claws, and Baleen.” In S. Ogden, ed., Caring for American Indian Objects. St. Paul, MN: Minnesota Historical Society Press, 2004, pp. 119–125.

© Government of Canada, Canadian Conservation Institute, 2018

Published by:

Canadian Conservation Institute

Department of Canadian Heritage

1030 Innes Road

Ottawa, ON K1B 4S7

Canada

Cat. No.: CH57-4/6-5-2018E-PDF

ISBN 978-0-660-27975-6

Page details

- Date modified: